Guide Placement

by Al Campbell

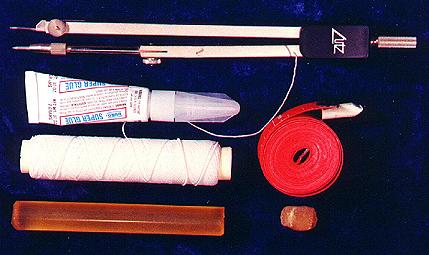

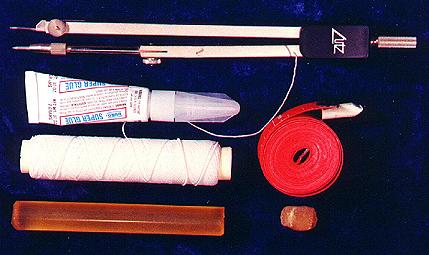

Guide placement is an important factor in any rod. Get it wrong and

your rod won't perform properly, or it will break. If you've purchased a

quality blank, marked the spine properly and have the guides spaced

right, you'll have a fly rod that will perform as good or maybe better

than the factory equivalent. Right now though, you have to space the

guides right. Here's a view of the tools I use to space and attach the

guides to the blank.

If you can, find a fly rod in the size and brand you

will be building and measure the guide spacing. If you can't find that

particular fly rod, you might write or call the rod company who made

the blank and ask for a spacing chart for that specific rod. Most rod

companies will share this information if you ask.

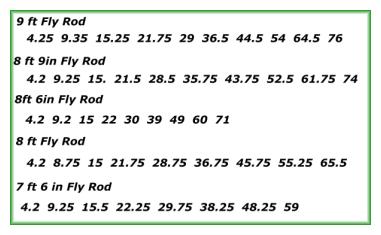

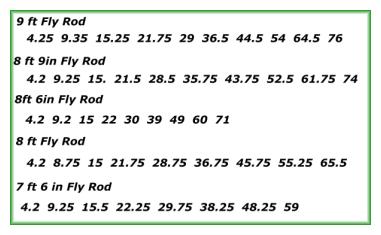

If all else fails, here's a sample spacing guide for

most of the common fly rods you might build. All measurements are

from the tip of the rod in inches with all of the sections assembled

In some cases (three or four piece blanks) you will have to alter this

spacing to accommodate the sections.

Mark where the guides should go with a piece of

bee's wax or a wax marker. That way you can easily wipe your marks

off the blank when you have the guides secured firmly in place. Be sure

to mark on the side of the spine so your markings won't interfere with

guide placement or wrapping. Never mark guide placement with anything

that will scratch the blank or is permanent.

When placing guides on the blank, work from the

bottom to the top. For the bottom section, you can place a reel in the

reel seat to help you align the first guide. Take your time and be careful

to get each guide aligned properly. You only get one chance to do this

right so don't get in a hurry and mess it up.

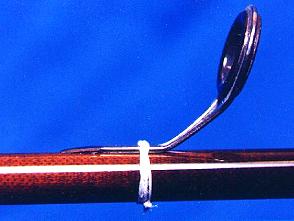

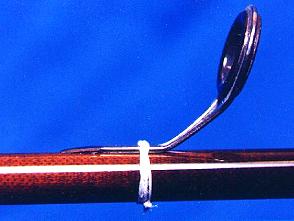

I use a piece of elastic string to hold the guides in

place. You can find this elastic string at a fabric store. Some people

use masking tape for this job, but I've found elastic string to be easier

to use when I'm aligning the guides.

To attach the guide to the rod, carefully set the guide on the

blank as close to the right position as you can manage.

Hold the guide and one end of the elastic with one hand while

wrapping the elastic around the blank with the other hand. After

three or four wraps, tie the string off and trim close to your knot.

To attach the guide to the rod, carefully set the guide on the

blank as close to the right position as you can manage.

Hold the guide and one end of the elastic with one hand while

wrapping the elastic around the blank with the other hand. After

three or four wraps, tie the string off and trim close to your knot.

Once you have the guide tied off, check to see if it's still

positioned on the spacing mark. If you've used elastic string,

you can easily move the guide back to the spacing mark if it

moved while you were tying it to the blank.

When you're sure you have the guide on the spacing mark, align

the guide with the reel seat or the spine mark, depending on

which section of the rod you are working with. Again,

take your time and get it right.

Once you're positive you have the guide in the right place

and aligned properly, apply a very small drop of super

glue to the tip of the guide foot. Use the corner of a paper towel to

soak up any excess glue. If you're using traditional guides with two

feet, glue the other foot down also.

The first guide on any section of the blank will be the hardest

to align. It's also the most critical guide on that section

to align. All of the other guides on that section will be

aligned to that guide. Before you glue any guide down, check

it again to make sure you have it aligned and positioned properly.

You don't want crooked guides and you won't get a second chance

after the glue has dried, so check it again before you apply

that drop of glue.

Once you have the first guide glued in place, the rest

are simple. Like the first one, place the guides in the right spot on the

blank and tie them down with elastic thread. When you have them in

the right place, turn the rod over so the guides are on the bottom.

Holding the rod in front of you, look down the blank and slowly rotate

the blank until you have centered the first guide on the blank and an

equal amount of the guide is visible on both sides of the blank. A lamp

shining on a white or near white wall will help you with this step.

After you have the first guide centered on the blank, look up

the blank to the next guide. Any mis-alignment will be very

visible to your eye. Slowly slide the guide you are centering

around the blank until it's aligned with the first guide, then check it

several times until you are certain you have a perfect alignment.

the blank to the next guide. Any mis-alignment will be very

visible to your eye. Slowly slide the guide you are centering

around the blank until it's aligned with the first guide, then check it

several times until you are certain you have a perfect alignment.

When you are certain the second guide is aligned properly, glue

it down and move to the next one. Align every guide with the

first guide you put on the rod. That way you will avoid

something called guide creep (the guides creep slowly around the rod)

which is caused by not having a set reference point. One by one, you

will place the guides on the blank, align them to the first guide, and glue

them in place. Use the same method to glue the tip-top in place,

except you need to use hot glue for the tip.

I've found guide alignment takes as long or longer to do than

wrapping the thread on the guides. Take your time and get it

right. No one wants to fish with a fly rod that has crooked guides.

Next week we'll start wrapping thread on the guides. Until then,

have fun with the guides, and if you have a moment, go catch

a fish. It's good for the attitude. ~ Al Campbell

|

the blank to the next guide. Any mis-alignment will be very

visible to your eye. Slowly slide the guide you are centering

around the blank until it's aligned with the first guide, then check it

several times until you are certain you have a perfect alignment.

the blank to the next guide. Any mis-alignment will be very

visible to your eye. Slowly slide the guide you are centering

around the blank until it's aligned with the first guide, then check it

several times until you are certain you have a perfect alignment. To attach the guide to the rod, carefully set the guide on the

blank as close to the right position as you can manage.

Hold the guide and one end of the elastic with one hand while

wrapping the elastic around the blank with the other hand. After

three or four wraps, tie the string off and trim close to your knot.

To attach the guide to the rod, carefully set the guide on the

blank as close to the right position as you can manage.

Hold the guide and one end of the elastic with one hand while

wrapping the elastic around the blank with the other hand. After

three or four wraps, tie the string off and trim close to your knot.