Creating Your Personalized Fly Rod Handle

by Al Campbell

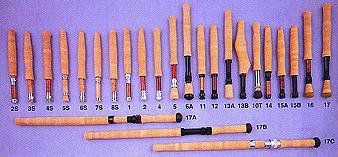

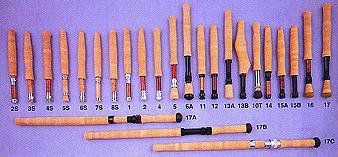

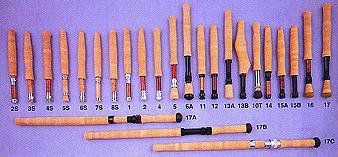

Fly rod handles can be as personal as you want to make them. If you

look in the catalogs, chances are you'll find more handle types than

you thought were possible. For instance, here's a look at the

handle selection in the Anglers Workshop catalog. If you want

to take it a step further, you can create a handle that fits the contours of

your hand and looks nicer than any you'll find in a catalog.

It doesn't take a lot of work to make your own handle. You might

have to do a little bit of shopping at the hardware store for some

of the materials you require. If you have a lathe that accepts a drill

type chuck, great. If you have a rod lathe, it's even better. You

don't have any of these things? No problem, a drill will do the job.

With a little creative thinking, you can turn a drill into a handle

lathe in no time.

The first thing you'll need to create a handle is some cork. I like

to use burl cork, a type of cork with swirls of dark color. This

is a hard cork with an inconsistent grain, but it makes beautiful handles

that will give any rod a custom look. You can purchase burl rings at

Anglers Workshop, Bob Marriott's and many other cork suppliers. Be

sure to purchase twice as many cork rings as the handle's length in

inches will be, they come in 1/2 inch thickness.

You can glue the rings to the rod blank, but you'll need a rod lathe

to turn your handle if you do. Most people form the handle off the

rod, and then fit it to the rod after it's formed. It's your decision on how

you want to do it. For now, I'll show how to create a handle off the rod.

You'll need a cork ring clamp. You can fashion one of these tools

from a 12 inch threaded rod that's 1/4 of an inch in diameter. In

addition to the threaded rod, you'll need two large washers and two wing

nuts that will fit the rod.

While you're at the hardware store, pick up some Weldwood Plastic

Resin Glue. I've tried dozens of types of glues over the years,

but the Weldwood glue you have to mix yourself is the best cork glue

I've used. You'll also need to pick up a 12 inch section of smooth

1/4 inch steel rod to insert in a drill so you can turn the handle

while you sand it. Oh, don't forget 60, 100 and 320 grit sandpaper

for sanding the handle into shape.

You'll need some type of cork filler and sealer when you get the handle

sanded to the shape you desire. U40 Cork Sealer is an excellent

sealer that's available from most rod component catalogs. I've also

used water based polymer sealers that you can find at the hardware

stores with good results. The best filler for burl cork that I've

found is walnut colored wood filler, (almond color for regular cork);

also available at the hardware store.

The first step in creating your custom handle is to glue the cork rings

together. First place a washer and one wing nut on the threaded rod,

leaving enough room to attach a drill to the end of the rod. Mix

the plastic resin glue to a consistency slightly thinner than regular

wood glue. Slide one cork ring down the threaded rod until it is

resting firmly against the washer. Apply an even coat of glue to

one side of each cork ring and slide the ring down to the previous

ring. Repeat this process until all the rings are glued together

and stacked on the threaded rod. Slide the other washer on the

rod and secure it tightly with the remaining wing nut. If glue seeps out

of the joints and the wing nut is hard to turn, you have the clamp

tight enough.

You will need to place the clamped rings in a warm place to dry

for at least 12 hours for firm glue joints. If you have glued

the rings properly, the joints should be stronger than the cork rings.

Once the rings have dried, remove one of the wing nuts and washer.

Using a drill attached to the other end of the threaded rod,

reverse the drill's direction and turn the cork 'blank' off

the threaded rod. You will now have a handle blank that is

ready for shaping and sanding.

The next thing you need to do is place the handle blank on your

lathe if you have one. If not, balance the smooth steel rod in

your drill, turning it 1/8 of a turn at a time until all the

wobble is removed when the drill is running. Then, slide the

handle blank onto the steel rod. Running the drill will make

sliding the handle onto the rod easier.

Fasten the drill to a solid object to hold it steady while sanding

the handle. If you don't have a way to fasten it, you can squeeze

it between your knees, but this is not as steady as a firmly

supported drill would be.

Start sanding the handle with the coarse sandpaper. Stop the

drill and check the handle dimensions often to insure a proper fit.

If you have a fly rod with a particularly comfortable handle, you might

want to measure its dimensions to make this handle fit the same way.

After you've achieved the approximate shape you want, switch to

a finer grained sandpaper to further define the handle. Keep

switching to finer sandpaper until you have a smooth handle

with the right fit for your hand.

Fill any voids in the handle with wood filler and sand until smooth.

It's easier to sand the wood filler when it is semi-hard than it

is if you wait for it to dry completely. Be sure to use fine sandpaper

and don't sand any more than is needed to remove the excess filler.

After you have filled the voids in the handle and the filler has

dried, you should apply a cork sealer to the handle to prevent any

opportunity for the cork to absorb water or solvents. Sealing the

cork also makes it easier to keep the handle clean. If you use

a polymer type sealer, you will need to apply two coats. A light

buffing with fine steel wool after each coat will smooth the handle's

surface and create the proper surface for a second or third coat

After the sealer has dried, place the steel rod in your drill.

While the drill is turning slowly, remove the handle from the

steel rod. Your handle is now ready to use on a fly rod.

Keep the drill handy; it will be useful when you file the inside

of your handle to fit the rod blank. Next we'll select a reel

seat and assemble it properly. Until then, may your fly line

be tight with fighting fish. ~ Al Campbell

|