Creative Foam Fly Tying

Dremel Bugs

By Jim Hatch

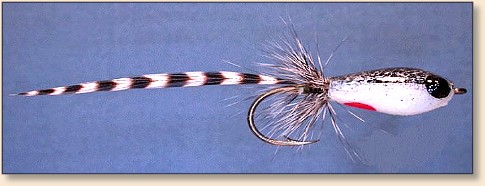

Photo Shad Slider by Bruce Harang

I'm not sure who first came up with the idea of using

a Dremel motor to spin foam plugs while turning them

into buggy critters with a common emery board. Capt.

Paul "Qrrfish1" planted the seed in my mind last spring.

Since then I have spent hundreds of hours doing just that.

I have made some money at it as well as a number of new

friends while sharing information on the process. I

continue to get requests for information and hope that

you too will find this useful.

Generally, the top water foam flies are thought of as

warm water bluegill and bass patterns. Nothing could

be further from the truth. There are few fisheries

that do not entail some surface fishing. That said,

foam flies do NOT have to be fished exclusively on

the surface. A bit of lead wire can make sinking

or suspending flies of most patterns. It may well

be that you are committed to fishing creations of

fur and feathers exclusively. The fact is fur,

feathers and foam can be combined to create some

very effective flies. It is an area that has not

been fully explored and there are many patterns begging

to be created. This article is intended to provide the

basics of working with foam as well as a few ideas for

effective fly patterns. It is intended to provide you

the tier with another tool and perhaps spark an interest

in creating something a bit different.

1. Dremel: The dremel is a motorized tool that

is well designed, readily available, economical, and easily

repaired or rebuilt with readily available parts if necessary.

There are other brands of rotary tools on the market that

can be used but my preference is for the Dremel for the

above mentioned reasons. I do not recommend the battery

powered models based on my experiences with them. The usual

disclaimers apply.

2. Foot Control: A foot control for your motor is

a very handy accessory which leaves both hands free for

working on your creations. The variable speed foot

control made by Dremel is pricey and is used only with

the single speed Dremel. The variable speed Dremel however

can be rigged up with a simple spring loaded foot switch

to turn it off and on. This is more than adequate and much

less expensive.

3. Extended Flex Shaft: Using the extended flex

shaft sold by Dremel will simplify construction of a Dremel

lathe as well as extend the capabilities of the Dremel for

other tasks.

4. Foam: There are many sources of closed cell foam

available for making foam bodied flies. My favorite is the

foam flip flops (not to be confused with the sponge rubber ones)

and they are available at many locations in season. They come

in a multitude of colors. Childrens foam puzzles are another

colorful source of foam. They can often be found in the

toy sections of thrift shops quite inexpensively. I have

also found colored foam garden kneeling pads to be suitable

and very economical.

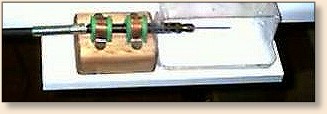

Constructing your Lathe

The photo below shows a very simple design for a foam

turning lathe. It uses a piece of scrap 2" x 4" wood

stock, two conduit clamps, 4 wood screws, and two small

pieces of flip flop foam. Simply attach the chuck end

of the Dremel flex shaft to the 2x4 with the two conduit

clamps and 4 screws using the foam to pad the shaft.

If you elected to use Dremels variable speed foot switch,

you can skip this part. If not, you can purchase a

simple push switch, not unlike a doorbell switch, that

makes contact when depressed and turns off when pressure

is removed. This is a very handy feature to have while

turning foam as it will leave both hands free to work with.

For simplicity you can wire such a switch into either leg

of a simple extension cord and plug your Dremel motor into

it. Place the switch on the floor where it is comfortable

to reach. Take care to ensure compliance with local

electrical codes as well as common sense. An exposed

electrical connection is an accident looking for a place

to happen.

Lathe Setup

The first step in setting up your lathe is attaching an

upholstery needle to support your foam stock for turning.

I purchased a Dremel collett from my local hardware store

to fit the 2 ¼ " straight upholstery needle I selected from

an assortment at Walmart. It is imperative that the collett

fit the needle to prevent unwanted vibration. I have used

the one needle for several hundred hours without the need

for replacement. The tools you use with this lathe for

removing the unwanted material from your creations is a

common emery board. A package of 10 should be under

$1.00 and will last for some time.

Preparing Foam Plugs for Shaping

Initially, I used short sections of sharpened copper tubing

chucked in my drill press or electric hand drill motor to

punch plugs of foam for shaping on my lathe. I recently

found a set of gasket punches that work much better and

the plugs are self extracting. They came in a set of 12

ranging in size from 1/8" all the way up to ¾" at a price

of only $5.50 for the set. I am told that Harbor Freight

has them as well and I know that they are sometimes available

on E-Bay for similar prices. Highly recommended! The

larger four sizes of punches were too large to chuck in

my drill press. A friend turned them down for me on a

metal lathe. He charged me a dozen foam flies for doing so.

Making "Dremel Bugs"

If you have stuck it out this far, you are now down to the

meat and potatoes of dremel bugs. You will begin by

attaching a suitable foam plug to the needle chucked in

your lathe. Carefully push the plug onto the needle

while applying several taps to the foot controller

supplying power to the dremel. After you do a few,

you will find they are centering much better and you

will be more competent at doing so. Begin your shaping

by running the rough flat side of the emery board lightly

across the spinning foam plug. This will quickly center

the plug should it be off a bit. Now, by applying either

a rough edge or a smooth edge of the emery board to the

plug, you will be removing material at a good rate. You

should ensure that your emery board remains 90 degrees

in relation to the needle. Of course the rough edge will

remove material more quickly where as the smoother edge

of the emery board will provide more control. You will

quickly be able to discern which is appropriate and when.

A smooth steady hand lightly applying pressure is the key

to success. If you are too heavy handed either the foam

will spin on the shaft glazing it and causing further

spinning or the material will disappear quicker than

the speed of thought resulting in very unusual designs.

A few plugs turned on the lathe will quickly show you what

works much better than I can put into words. Just keep in

mind that a light smooth touch will result in a much nicer

finished product.

Okay, that jerk has talked you into buying a Dremel, building

a lathe, and spending considerable time searching department

stores for suitable foam. Let's make something useful!

Set the speed on your Dremel to about half speed. Chuck

a foam plug. Lightly center it by applying pressure with

a flat emery board. Not too much. Start at one end with

the emery board at an angle and apply a taper to the foam.

You just made a popper body. It should have taken you about

15 seconds. Have you priced unfinished popper bodies lately?

You just saved some money. Do it again. This time add a bit

more shape to it. Now with any luck at all, you have a "sexy"

popper body. Not the standard taper, but something just a bit

nicer. How about that. Just saved more money. Let's try

another. Remember the old Hula Popper by Fred Abergast? Piece

of cake. But yours will be a genuine light-weight fly, not

a hunk of wood or plastic that would take your head off.

If you rest the end of the emery board against the needle and

the foam where the hook eye will eventually protrude, you can

cup it like the original Hula Popper. Zara Spooks, diving

crank baits, floating clousers, jitterbugs, floating nymphs,

or sinking nymphs with a bit of lead wire. The sky is the

limit. Remember those neat round headed sliders that worked

so well on your gills before they got so hard to get? I think

they were called Dennies or some such. Well, they just got

easier to find. Pop another piece of foam in the lathe and

turn some balls.

How about a mayfly imitation that really

will float all day? Yep, it's hiding the same place these

other kritters were. Right there on your little foam lathe.

Add a bit of imagination and the possibilities are virtually

endless. I have worked my way through a book of entomology

with foam reproductions of the kritters within and have yet

to be stymied. Shape got you stumped? Think multiple shapes.

Yes, you can easily and permanantly attach different shapes

together with CA adhesive.

How about a mayfly imitation that really

will float all day? Yep, it's hiding the same place these

other kritters were. Right there on your little foam lathe.

Add a bit of imagination and the possibilities are virtually

endless. I have worked my way through a book of entomology

with foam reproductions of the kritters within and have yet

to be stymied. Shape got you stumped? Think multiple shapes.

Yes, you can easily and permanantly attach different shapes

together with CA adhesive.

You can also use it to attach your foam bodies to a thread

wrapped hook with your choice of hackle or hair. The CA

purchased from model hobby shops is available in different

viscosities and drying times. I find that the 25 second

thick CA is ideal for use with foam. Not only is the

marriage permanent but the 25 second drying time should

allow you to position the body on the hook before it cures.

Speaking of hooks, I find that the standard Aberdeen style

hooks are well suited for almost all of my foamies. And at

about $3.00 per hundred instead of what you have been paying

for hooks. The Mustad or Eagle Claw Aberdeen hooks are stocked

by almost all angler or bait shops. See, you just saved some

more money. It want be long before you are in the black on

this new foamie lathe setup. Go ahead and play with it for

a bit and don't be afraid to try different shapes. They

will become easier with practice.

Speaking of hooks, I find that the standard Aberdeen style

hooks are well suited for almost all of my foamies. And at

about $3.00 per hundred instead of what you have been paying

for hooks. The Mustad or Eagle Claw Aberdeen hooks are stocked

by almost all angler or bait shops. See, you just saved some

more money. It want be long before you are in the black on

this new foamie lathe setup. Go ahead and play with it for

a bit and don't be afraid to try different shapes. They

will become easier with practice.

Finishing your Creations

Well, here you are with a pile of foam bodies. Now we need

to convert them to flies. Many of you need no further

coaxing but I will elaborate anyway. Even though you were

just playing, er, uh, practicing with your new Dremel lathe,

you undoubtedly came up with some neat new bodies that just

happen to match the desired hook size. Oops, didn't I mention

that? Yes, it is entirely possible and highly recommended

that you design your Dremel bugs to fit specific hooks. With

the Aberdeen style hooks you need concern yourself only with

the length of the shank and the hook gap. Got to have room

for Moby Fish to get to the point. In the case of many fly

styles, you will begin by making a thread wrap on the hook

shank and tying in suitable hackle or hair for tailing.

Then after applying a scant drop of CA adhesive to the

thread wrapped hook shank, you can slip the body over

the eye of the hook and quickly position it before the

glue sets.

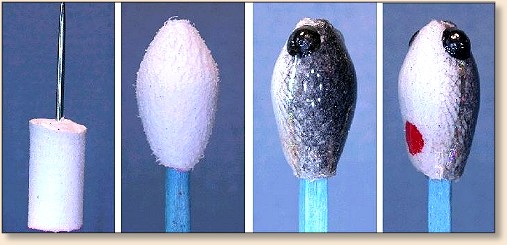

Whenever possible, I prefer to pre-finish my bodies prior to

gluing them to the hook. In some cases this is simply

gluing on or painting on eyes or in others applying a

scale effect through a piece of sheer curtain fabric

with canned spray paint. On some flies you may desire

to add other details with pens or paint sticks. Often

times I will apply an epoxy finish to a completed body.

The epoxy results in a high sheen and provides long term

protection for the body. In any case I prefer to make my

flies using foam of the desired color for my basic body

color and adding the accents I deem necessary or appropriate

for the pattern. When I have glued the body to an already

thread wrapped and tailed hook, the fly is completed unless

legs are desired. You can insert a needle through the bodies

in the desired locations to add appropriate rubber legging

materials. I like to apply glue to the legs near the body

and pull the glued area back into the body to ensure they

stay put.

Here's my set-up:

I have found fly tying with foam to be very enjoyable and

every bit as addictive as any other style. I do hope you

will decide to give it a try. If you have questions or

comments please email me at: ~

Jim Hatch

Happy Tying

|