Texas Foam Midge

By Hillfisher, Texas

I have been itching to go fishing but the last few days

have been rainy with a few snowflakes mixed in here and

there. During these brief but intense storms, the bream

and bass go deep and will not take anything. It's a good

time to catch up on tying and chores around the house.

The last storm lasted only three days but temperatures

reached the 20's during the nights and 40's during the day.

My hat is off to my northern brothers who can put up with

this for long periods of time.

Today the eastern sky dawned clear and bright and the

temperatures are to reach the upper 60's. I have a lot

of wood to chop from the big storms we had this last spring

and figured I would get a good start on it. This is actually

one of my more favorite chores. Mostly because I get to

play with large sharp objects (ax) and power tools (chainsaw).

After a little warming up I'm really getting into the wood

chopping. Every piece the perfect length and stacked by size.

After a couple of hours I have made some pretty good progress.

Then I made a mistake. I took a break and while I was sitting

there I heard water being slapped in the creek. Hmmm . . ."I better

check this out." I thought to myself and proceeded down to the

bank. There were rings everywhere! When I approached the edge

of the creek the bream were startled and several tail slaps were

observed as they turned and headed for deeper water. I squatted

down and waited for a time and soon they were once again rising.

They were feeding so actively that at times the water being

slapped as they would partially clear the surface feeding.

Ok that's enough wood chopping for today! I ran, literally,

back up to the house and grabbed my 5wt and hip waders, which

I keep ready in the garage just for days like this. Under a

slight bit more control, I walked back down to the creek and

very carefully waded into position. After a few minutes there

were rings forming all around me. Some of these fish were

rising within three feet of me. They were all bream. This

was going to be a great afternoon!

I started with a surface yellow spider but after a few casts,

it was apparent they did not give a darn for yellow spiders.

I tried a variety of other surface flys but to no avail.

This was really exasperating! I was watching these fish

actively rise to feed all around me. I tried a nymph about

size 12 and started getting taps and an occasional hook up

with some small bream, but nothing compared to the activity

I was seeing around me.

I stopped casting and watched the water around me. The afternoon

sun had produced enough warmth to cause a hatch. There were some

very small flies hatching on the surface and I mean some really

small flies. The bream were selectively feeding on these. I

carefully waded out of the creek and went straight to the tying

table. Not wanting to spend a lot of time spinning dubbing etc.

I went straight for the foam. I know for some fly tyers the use

of foam is just not considered to be the true art of tying and

in some ways I do tend to agree. However for speed, likeness

and performance, foam is quickly replacing a lot of natural

materials with the new generation of tyers. In a some cases

I will use foam to test the effectiveness of a pattern and

then switch to natural materials to get a more traditional

appearance.

All said and done the fly which came of the vise somewhat resembled

the hatch. It produced some nice bream that afternoon and the

next day. I think dubbing will produce a better fly and by

slightly varying the pattern to remove the wings and replacing

with a wing case will get the instant nymph pattern which was

also very effective. Below is the recipe and quick tying

instructions. Have fun!

Materials: Texas Foam Midge

Hook: Mustad 3399D size 18.

Thread: Thread 6/0 black.

Body: Body brown foam strips in 1/16 x 1/8 x 3 inches.

Rib: Copper wire.

Wingcase: Optional - Peacock Hurl.

Wings: Wings white duck quill (Adult), Turkey (nymph).

Tying Steps:

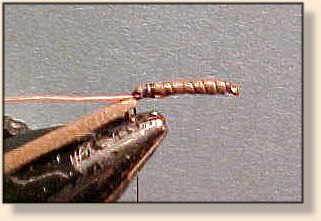

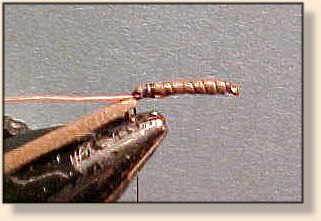

1. Create thread bed and start foam strip just behind

the eye of the hook.

2. Wrap foam back to bend of hook. Wrap thread over foam

to the bend of hook. Tie in copper wire at bend of hook.

3. Wrap foam up to just behind the eye. Wrap thread up to

just behind the eye in between the foam layers. Wrap thread

back to about two eye widths and let hang. Wrap copper wire

up to thread and tie in.

|