Tying Instructions:

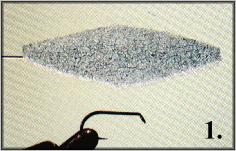

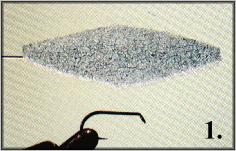

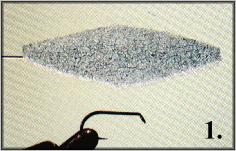

1. Color a section of Ethafoam sheeting and secure the color *as described

below, (or color the foam and then wait to brush on the thinned Flexament

after the fly is complete; I prefer this because it secures

all the thread turns.) Cut the colored foam into a diamond shape approximately

three full hook-lengths long by one hook-length wide. Color the edges

of the diamond if you like.

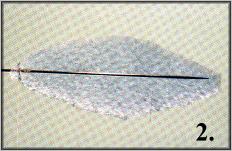

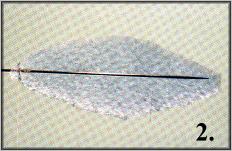

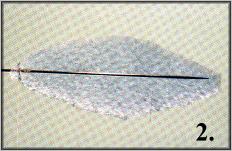

2. Mount a beading needle by it's eye in your vise as shown. Start the

thread lightly near the needle's center. Tie in one tip of the foam diamond

on the far side of the needle. The uncolored side of the foam should face

you and the bulk of the diamond should project away from the vise. Use

light thread-tension throughout the needle-tying.

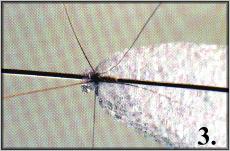

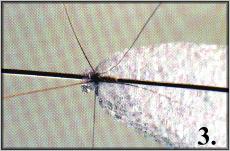

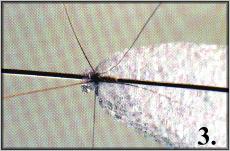

3. A tiny hump of foam should project beyond the thread turns. Hold

one tail hair above the foam and one below, take a light turn around

both, pull the turn snug enough to spread the tails. The tails should

project about 2 shank-lengths from their tie-in point, but this is

not critical. Do not trim the tail's butt.

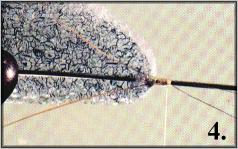

4. Bend back the diamond as shown, towards the vise. Wind the

thread down the needle and hair butts a turn or two.

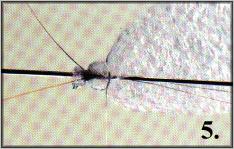

5. Bring the foam forward again, and then take two thread-turns

over it. The turns should be just tight enough to form a round

foam-segment.

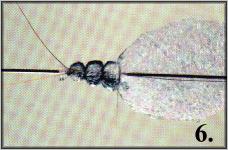

6. Continue forming segments, each slightly larger than the last,

until there are four. (The hump of foam between the tails counts

as a segment.) Half hitch the thread and trim it. Slide the

segmented abdomen off the needle.

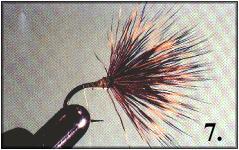

7. Remove the needle from your vise. Mount a hook in your

vise. Start the thread halfway up the shank; at this point tie in some

combed stacked coastal deer hair. The hair should project one-and-

a-half hook shanks from its tie-in point. Trim the butts of the hair at

an angle, and then bind the butts with tight thread-turns. End with

the thread at the bend. Half hitch the thread but don't cut it.

8. Remove the hook from your vise. Push the hook's point through

the center and out of the bottom of the last segment of the foam, opposite

the seam. Slide the foam up to the bend. Return the hook to your vise.

Take two turns of thread around the half-hitched thread that forms the

last foam segment.

9. Draw the foam down out of the way, then spiral the thread tightly to

just behind the eye, catching up the tail butts as you go. Trim the butts

closely. With your thumb nail, crease the hair back and up, and then

add tight thread-turns at the front of the hair to secure it upright.

10. Advance the thread to the eye again. With your left hand (right handers),

draw the front of the foam up again and around the sides of the shank. Add

firm thread-turns at the eye to secure the foam there.

11. Stretch the end of the foam as you trim it closely. Spiral the thread

back between the eye and the wing and take a full turn there. Then

spiral the thread beneath the wing to about halfway

between the wing and the bend. Take two turns there, spiral the thread

forward under the wing, and then take a turn between

the wing and the eye. Return the thread to the eye, build a thread head,

add a whip finish, trim the thread. (See the following illustrations for

thread wrapping the thorax.) Remember that, as Richard describes it,

the tightness and placement of the thread-turns "sculpts" the thorax.

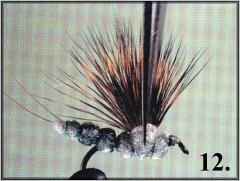

12. Cut a tiny slit in the foam on each side of the wing. Don't cut the

thread! (You have the option of cutting the slits before thread wrapping

the thorax - Richard prefers this - but for at least your first few Bunse

Duns, I'd suggest cutting them after.)

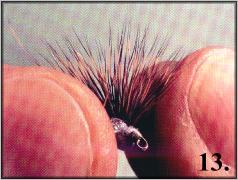

13. Pull the wing's hairs to the sides, into the slits. The wing should

now form a fan, a half-circle.

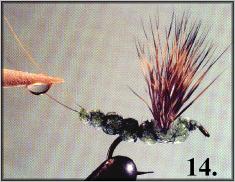

14. If needed, trim down the stub of foam between the tails, and

touch up the foam wherever needed with a marking pen. Add a

drop of highly thinned Flexament (three parts thinner to one part

Flexament) to the tail, to both of the wing slits, and to the thread

head (I don't bother with head cement). If you haven't yet secured

the foam's color, simply add Flexament at the points just described

and wherever needed to coat the color. Remember, thinned Flexament

flows well - a little is a lot. ~ Skip Morris*Coloring Foam

Ethafoam that is colored with a permanent marking pen should always

be given a coating of thinned Flexment (three parts thinner to one part

Flexament). This technique was developed by Richard Bunse. Richard

marks the foam with broad strokes of the marker, then lightly brushes out

the Flexament. "Lightly" is important here - Richard's brush merely

grazes the high points of the Ethafoam's textured surface. The thinned

Flexament spreads quickly. ~ SM

|