|

Recycled Plastic Fly Bodies and Hopper Legs

By Richard A. Lewis

2) learning a tactile skill

3) exploring the properties of polymers

4) creating unique and robust fly tying

components with your own two hands that you

simply can not purchase in a fly shop etc.

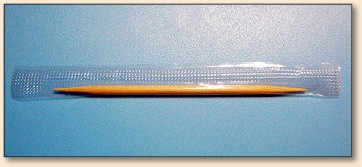

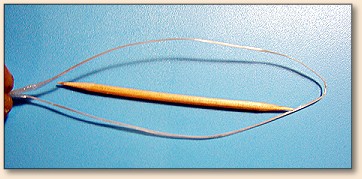

Step 1 - Carefully slide the toothpick to

one end of the wrapper and extract it from the

sheath without crumpling the plastic material.

You do not want to create nicks, creases and

flaws in the thin material. Put the toothpick

aside for later use.

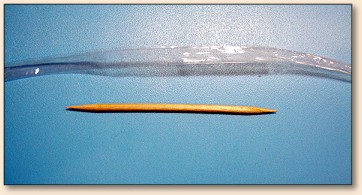

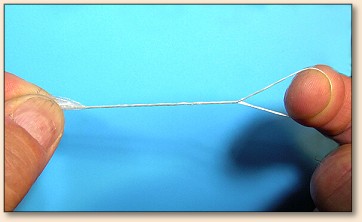

Step 2 - Firmly grasp the ends of the

wrapper between the thumb and fingers of each

hand. Pull slowly, smoothly and deliberately

on the wrapper until it is taught. Further

continue to apply tension until you feel the

plastic wrapper give and stretch. If it tears

or snaps in two; you are either being rough,

or the cello-wrap is too brittle or not fresh

enough. Try again using a better technique (a

learned skill) and or another batch of toothpicks

(try another café). As the wrapper stretches,

it becomes thinner and flatter as pictured above.

The wrapper is originally 3 1/2 inches long.

When carefully and completely stretched-out flat,

the wrapper can be coaxed into a ribbon which

has a length of 14 inches! With practice you

will find the elastic limit of the stretch-formed

plastic and be able to routinely make these ribbons

with minimal breakage.

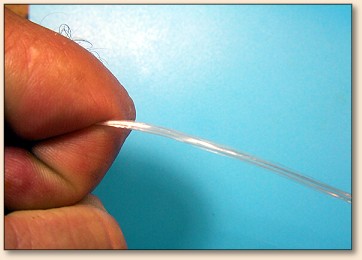

Step 3 - Next we will draw the flat

ribbon into a filament. Grasp the ribbon

in one hand and wedge it into the clinched

fingers of the opposite hand as shown above.

Slowly apply firm pressure and "draw" the

ribbon down into a strand, which we will

call a "yarn."

There is friction created by the filament

drawing operation; therefore some heat is

generated. So be gentle on your hands and

gradually continue to draw-form the ribbon

along its length until you have drawn it

into a very thin solid yarn. It becomes

strong and can withstand a good solid pull

at this point. This takes some practice.

Devise a grasping and drawing technique

that works for you with minimum discomfort

and good results.

Once completed, you will have stretched and

drawn a 3 ˝" two-ply plastic sheet into a

17.5 inch long yarn. Now that is 500%

elongation; a demonstration of an amazing

property of the particular plastic alloy

used in making toothpick wrappers. Science

and fly tying merge!

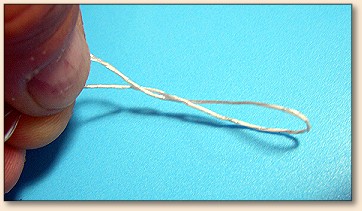

Step 4 - Fold the yarn in half. Grasp

both ends with the fingers of one hand.

Step 5 - Insert a finger into the formed

loop and twist the loop in a circular, clockwise

motion. Wind it up tight. On a full-length yarn,

I like to put a minimum of thirty (30) twists

into the loop. Apply tension as you twist.

When the loop is twisted it will look something

like the yarn pictured above. Don't let go of it

your loop just yet! Keep your finger in the loop

and maintain tension to preserve the twists.

Step 6 - While preventing your loop from

unwinding, slip your finger out of the end of the

loop. Now fold the twisted yarn in half once more.

This time it will want to furl upon itself due to

the stored energy within the yarn.

Step 7 - Help the furling process along

by twisting the yarn counterclockwise while

pinching both ends together. Twist it up tight

all along its length. Once twisted, smoothed,

stretched and compacted, the furled yarn,

which is technically a twisted filament yarn,

will stay combined all on its own. With the

method perfected-it takes but two minutes to

furl a wrapper into a damsel fly body.

I find that these plastic furled yarns are

very stable and will keep their shape for

weeks on end. I make these when taking lunch

breaks, talking on the phone and while gazing

out the office window wishing I were tying or

fishing. You get the idea. Once you have the

technique mastered, you'll want to have a

supply of these furled yarns on your tying bench.

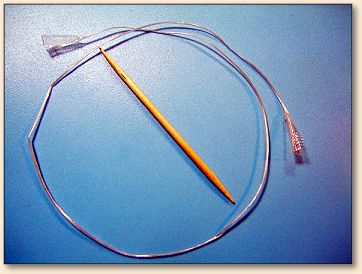

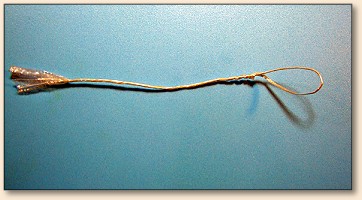

The hopper's leg pictured above was made

by bending the furled yarn and freezing

the joints with CA adhesive. A drop of Epoxy

(Loon UV Knot Sense in my example) can be

added to thicken the upper portion of the

leg for a more realistic hopper leg imitation.

These furled plastic yarns are buoyant,

and are easily colored using felt tipped

markers. The furled yarns can be fashioned

into damsel bodies, hopper legs and probably

a few other fly parts too. CA adhesive

(Zap-A-Gap) adheres well to this recycled

plastic, and allows the yarns to be formed

and shaped with ease.

There you have it. A method to recycle your

way to more interesting, cost effective flies

while entertaining your buddies at lunch.

Have fun! ~ Rich Lewis

|