"Do you really tie your own flies on THAT?

When I demonstrate fly tying on my

extremely-low-budget and easy-to-build

fly tying vises at public fly fishing

gatherings that question is often directed

towards me. The answer is yes.

"Why would you do that?" is a frequent follow-up

question. I have led Boy Scouts and 4-H youth

in introductory fly tying lessons. These sessions

in fly tying have begun with vise building. When

students build their own vise they invest their

sweat in the finished product. This sweat equity

instills a sense of ownership in the finished product.

There is also the benefit that the student can

tie flies when the course is completed without

the need to immediately invest in equipment.

Young people are very quick to ask if this "thing"

that they are building will really work or if it

is just some "hair brained" idea. The best way

that I know to convince them is to look them

straight in the eye and say, "I tie on a vise

like this all of the time, now sit down and I

will lead you through the steps so that you can

tie your first fly."

Another reason that I tie all of my flies on

homemade vises is that I can use my tying

experience to improve the design of such a

vise and to explore its strengths and limitations.

One of the strengths of this vise is that the

X-acto knife handle can be removed from the

vise with the nearly finished fly still attached.

You can then inspect the fly and make final

adjustments to the fly such as trimming of

flash and rubber hackles, or paint eyes on

the fly while you view the fly from a variety

of angles. I tie flies on hooks that range

from size 20 to 1/0. However, this vise is

at its best for hook sizes 18 to 4. This vise

is named in honor of a friend who suggested that

one of my earlier vise designs might be difficult

for many to construct. His comment prodded me to

develop this vise.

In addition to tying flies on the vise shown

here, I also construct fly tying vises with

bases from unusual items. They include recycled

barn door hinges, frying pans, a telephone, copper

pipes with attached valves, and half of a bowling

ball. They do attract onlookers at fly fishing

and fly tying events. I haven't made one from a

kitchen sink...well not yet anyway.

The critical component in a vise is the

mechanism that actually holds the hook.

For this vise, an X-acto knife handle

holds the hook for tying. It is held to

the piece of plywood with a 5/16 wire rope

clip (also known as a cable clamp). The

wire rope clip is held in place by a wing

nut and a flat washer on one side of the clip.

(The other side of the wire rope clip is left

without a nut). The plywood is attached to

three pieces of 2 X 4 to provide a stable base.

Nails and glue or screws and glue can be used

to attach the wood pieces together.

Follow these steps to place a hook in the

vise. As with any tool, there is a learning

curve before mastery is achieved. By following

this sequence you can become comfortable with

this vise after just a few tries.

1. Loosen the knurled sleeve on the vise.

(Loosen just until you can squeeze a hook

into the jaws of the knife handle.)

2. Position the hook so that the angle formed

by the hook shank and the centerline of the

knife handle is approximately 45 degrees.

3. Tighten the hook by pulling the knurled

sleeve towards the hook while rotating the

knurled sleeve. (Remember Righty - Tighty!)

4. After the hook is sufficiently tightened,

position the hook in the vertical plane by

inserting the knife handle in the wire rope

clip and tightening the wing-nut on the wire

rope clip.

Construction Notes:

A rectangle of 3/8 plywood is much stronger

when the direction of the grain of the top

and bottom plies runs parallel to the longer

sides of the rectangle.

A piece of non-slip rug cushion or non-slip

shelf liner attached to the bottom of the vise

will keep the vise from sliding on a smooth

surface.

To locate the holes in the plywood measure

the wire rope clip to determine the distance

between the legs of the threaded "U" rod.

(There may be variation between different

manufacturers and styles of wire rope clips.)

Center the wire rope clip holes 1 ½ inches

from the rounded end of the plywood.

Happy tying.

Steve's Vise Parts List

1 X-acto knife handle - Type A handle

(5/16 handle diameter)

1 5/16" wire rope clip

1 5/16" flat washer

1 5/16" wing nut

1 3/8" plywood 4 ½" X 12"

3 12" pieces of 2 X 4 lumber

1 4" X 11" rubberized cushion or liner

1 wood glue

9 10d box nails (2 ½" screws can be substituted)

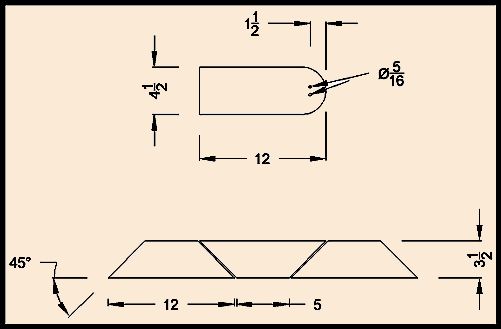

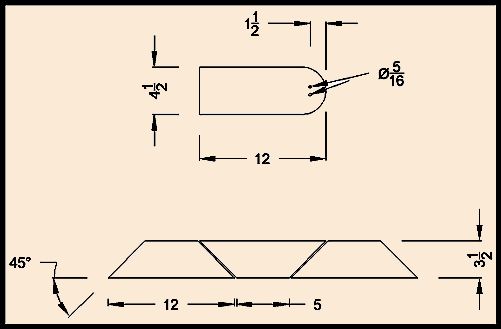

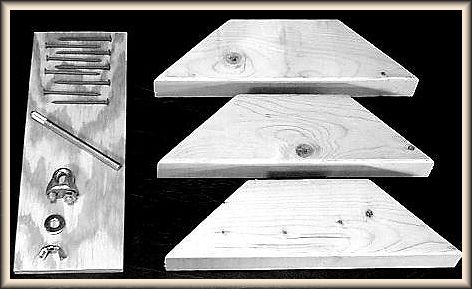

Figure 2. The layout of the pieces is shown

above. The piece shown on top is drilled with

two 5/16" diameter holes to receive the wire

rope clip which holds the X-acto knife handle.

The lower drawing shows the layout of the pieces

of a 2 X 4 for the base of the vise.

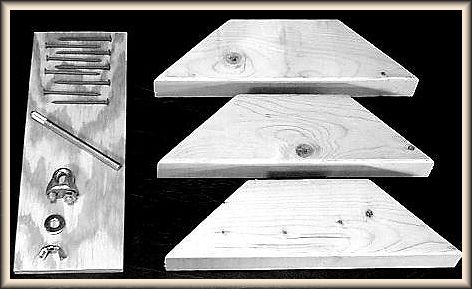

Figure 3. The essential parts of "Steve's Vise"

are shown above ready for assembly. ~ Ed Engelman

Please check out the Fly Tying Section, on the Bulletin Board, here at FAOL too.

If you have any questions, tips, or techniques; send them to

publisher@flyanglersonline.com

|