|

|||

|

January 18th, 2009 |

The Premiere OnLine Magazine for the Fly Fishing Enthusiast.

This is where our readers tell their stories . . .

A Special Rod for One Particular Stream

The Beauty of Rod Building

By Ed Temme (Smernsky)

|

Making the handle and choosing the cork. The green craft foam is added for color trim. The cork rings and foam are glued individually together on a mandrel (shown in the next picture).

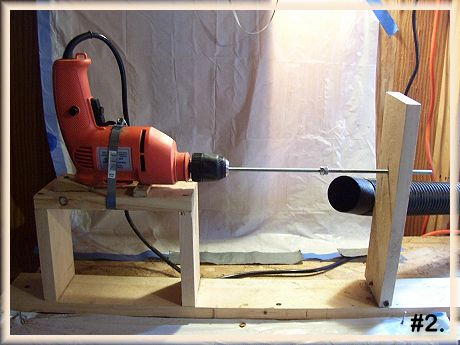

The cork and foam are turned to shape using (in this case) a home made lathe.

Pre fitting the completed grip to the blank.

Fitting and Epoxying the Reel Seat and Grips.

Inletting of Butt (just a fancy add on.)

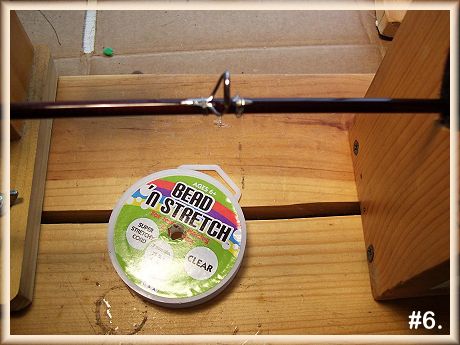

Placing and tying on the guides with stretch string (for repositioning if needed)

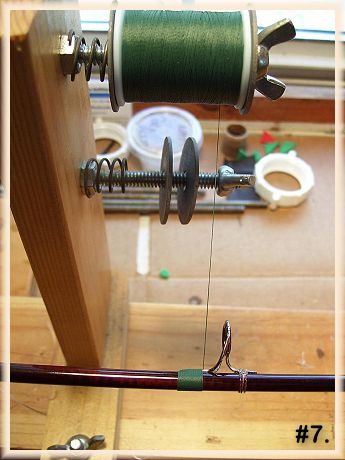

Thread and trim ring wrapping / after which coating with flex coat epoxy.

The completed Rod—ready to fish.

|