|

I was sitting in the family room the other day thinking about

fishing when I had a sudden revelation. I realized I had a fly rod up

on the fireplace that I had never cast. It was an old West Bend bamboo

rod I had gotten from my father-in-law many years ago. I thought

it would look nice up on the fireplace as an ornament. Now I have to

admit, this was before I really got into fly fishing and I wouldn't have

known how to cast it at the time. It just sat up there while I learned to

fly fish and bought all kinds of other fly rods and reels and stuff. So

here a quarter of a century later, I get the urge.

Now I am the first to admit, I am not the best caster in the world.

But I am afflicted with another malady. I am an engineer. So, as with

any other pastime I have picked up along the way, I am driven to

understand the engineering mechanics behind the tools of each

particular trade. That being the case, I have spent time reading and

studying and even writing about how this stuff works. Doesn't help my

casting any. It just satisfies that mathematical disease I am afflicted

with. And being so afflicted, I have gone through the same engineering

analysis with all of my other rods and compared those numbers with

how I think they feel. But I had never even gotten this rod down off the

fireplace. Oh what a fool am I! And here is why.

As true fishermen, most of us have evolved into the modern

culture of graphite composite rods and super slick PVC fly lines with

computer perfected tapers. We worship at the alter of Scientific

Anglers, and Sage, and Orvis et al. Please don't be offended if I didn't

name your favorite but you get my point. Now there are those who cling

to glass and bamboo and chortle at our madness. And thank God they

are still there to provide a mirror to our seemingly insane march

towards technology. We plod on, none-the-less. But eureka. Here I

sit with a perfect opportunity to get up off my duff and do a real life

comparison of the old and the new. So I got up and I took that rod down

from the fireplace. I also grabbed my Sage FLi 8 weight, which felt about

the same stiffness (I'll explain stiffness later) and I headed to the

workshop to play. My, what fun!

So where do we start. If you have read any of my writing on rods,

which can be found on my website www.HATofMichigan.org under the

"Mechanics of Fly Casting" articles (plug, plug), you will see that I

don't buy into words like fast and tip-flex and stiff and the like. They

are subjective. Yea, verily, even the line rating that most manufactures

put on the rod, is subjective and open to interpretation. It is

arrived at by an expert at the manufacturer casting the rod, as he thinks

you will cast it, with a number of different line weights. Now I admit

they are a little more scientific than that, but the truth remains, there is

a tremendous amount of variation within any given factory rating. So

much so that they even overlap when actually measured. "Measured

how?" you ask. Let me tell you.

In my opinion, there are two numerical quantities of any rod that

overwhelm all other measurable quantities. The first is its static

stiffness. This can be measured by clamping the rod handle

horizontally, hanging weights on the end, and measuring its deflection.

In simple engineering terms, it is its beam stiffness. There are a number

of subtleties in how you go about getting this number but the most

comprehensive database for rods was developed under Dr. Bill

Hanneman's "Common Cents" method. The resultant number is called

ERN and can be found along with a database in https://www.commoncents.

info/. There is more in that procedure than just ERN and you may

or may not agree with all the details. But, at the end of the day, this

procedure has resulted in the largest and most comprehensive

tabulation of fly rod static stiffness to date. Another data base can be

found on https://www.sexyloops.com/eric/database/rodtablesorted.php.

Look for the ERN number in these data bases for your rod if you like.

This value is the single most descriptive of how a rod will "feel" as you

load it against the back cast before you start your forward cast. It is a

measure of the capability of a rod to deliver energy to the line. That

being said, you must remember that this number is a static number. It is

what you will "feel" at the handle when you deflect a rod in a static or

quasi-static situation. It cares nothing about the material or the mass

distribution or the taper or anything else that may effect

the static qualities of the rod.

But a cast isn't static. So we need more. There have been other

attempts to gain knowledge as to how the mass distribution and taper

and section modulus et al effect the cast but, in my mind, the best so far

is an approach just developed by Magnus Argus, an editor and Chief

Reviewer of "Fly Fishing & Fly Tying" magazine out of UK

(www.flyfishing-and-flytying.co.uk). His procedure is a simple and non

destructive method and yields a number called MOI. MOI means

moment of inertia. It is an engineering term which in layman's words

represents the resistance of the rod to being rotated about the butt and

it is indicative of the force you must exert in the handle (feel) to rotate

the rod. So all those quantities we pay dearly for - high modulus

graphite, taper, low weight - show up here. The lower the number, the

lighter the rod will feel in your hand and the "faster" it will feel as you

rotate it. The data base being used to categorize rods is not nearly as

complete as the ERN data base but is growing

(https://www.sexyloops.com/eric/moi.php).

So there you have it. Two numbers, ERN and MOI. In my

opinion, all rods will be rated this way somewhere out in the future.

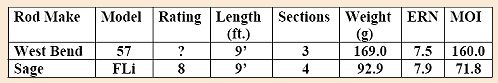

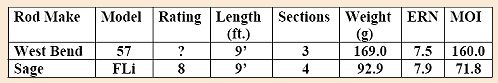

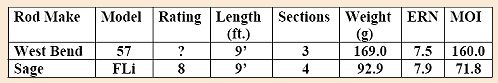

And here are the two rods I chose to compare.

First of all notice the ERN for the two rods is very similar. Now I

don't buy into the common notion that there is a significant effect by the

actual shape of the deflection path or shape of different rods. My

opinion is that it is the actual load that you "feel" and not the subtleties

of the actual shape of the deflection path. Now I know that many

manufacturers show fancy drawings showing some rods perfectly

straight two thirds of the way up and only the tip deflects and they call

these "fast." And they show others that bend all the way down to the

grip and call them by some other term, not as negative as, but meaning

"slow." Now really good and experienced casters say they can feel this.

But I cannot. In my opinion, the difference most people associate, in a

static sense, is the load. I think rods, rated the same weight by the

manufacturer but labeled "fast" and "slow," actually have different

ERN's. But to get out of this argument quick, suffice it to say these two

rods deflected along an identical path. So from a static viewpoint, these

two rods were nearly identical.

First of all notice the ERN for the two rods is very similar. Now I

don't buy into the common notion that there is a significant effect by the

actual shape of the deflection path or shape of different rods. My

opinion is that it is the actual load that you "feel" and not the subtleties

of the actual shape of the deflection path. Now I know that many

manufacturers show fancy drawings showing some rods perfectly

straight two thirds of the way up and only the tip deflects and they call

these "fast." And they show others that bend all the way down to the

grip and call them by some other term, not as negative as, but meaning

"slow." Now really good and experienced casters say they can feel this.

But I cannot. In my opinion, the difference most people associate, in a

static sense, is the load. I think rods, rated the same weight by the

manufacturer but labeled "fast" and "slow," actually have different

ERN's. But to get out of this argument quick, suffice it to say these two

rods deflected along an identical path. So from a static viewpoint, these

two rods were nearly identical.

Now notice that the MOI is markedly higher for the West Bend

bamboo rod. This means that a great deal of energy transferred from

the hand into the cast is going into just moving the rod. This will hold

true both in the acceleration of the rod in the forward cast and, perhaps

more importantly, in the stop. From a theoretical standpoint, this

should mean that the longer the casting arc used (for higher

line velocities needed for longer casts) the more difficult the stop is

going to be. When you reach the velocity where a crisp stop is no longer

possible, the loops should start to open and it will not be possible to

carry more line. Add to this the fact that the handle on the West Bend

rod is smaller and the problem will be exacerbated.

So with all these preconceived notions, I head out to the yard.

Casting Results (for me)

The Sage rod I chose just happens to be the one I cast a lot when

practicing for longer distances. I am not a good distance caster but on a

really good (lucky) cast I can get out the entire fly line. Most of the time

I can cast effectively out to about 85 feet. I can carry comfortably about

55 feet of line and shoot the rest. On the short side, I feel the rod looses

the sensitivity I like, with its rated line, at about 25 feet and below. Most

of my stiffer graphite rods that I routinely use on smaller rivers, I

usually over line by a size or two so I can cast shorter distances by feel

rather than just by timing alone.

So for me, the Sage rod is a nice, well behaved, and comfortable

rod at distances from 25 to 85 feet. Nicest range was around 60 feet. You

could cast all day at that fatigue level.

Now the West Bend was a club. I immediately started having

trouble with fatigue on any casts over 40 feet. Besides being much

heavier and more fatiguing, I started having trouble with line carry at

50 feet. The line would not shoot at all so maximum casts were around

60 feet. On the short side, the rod cast well at around 20 feet.

As far as double hauling and shooting goes, the problem with the

West Bend was the guides. The stripping guide was only 3.7 mm. It was

actually smaller than the tip top which was 4.2 mm. And there were

only 7 guides. This compares to a 10.6 mm stripping guide on the Sage

and there were 2. There were a total of 10 guides on the Sage plus a 4.2

mm tip top.

In summary, the Sage was much easier to cast at distance, would

double haul and shoot line far better, and was not particularly fatiguing

for all day 60 foot casts. The West Bend was a chore to cast at any range

past 40 feet and would not shoot line or double haul worth a damn. We

have come a long way in 50 years. I am glad. ~Bob Bolton

|