|

A quick search on Google.com or in your tying

catalogs will show you that there are many tying

benches available for your desktop. Most of them

share two major drawbacks. First, they cost too

danged much, and secondly, they were not laid out

specifically to fit your tying style.

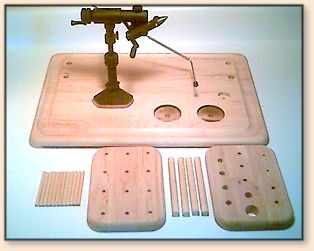

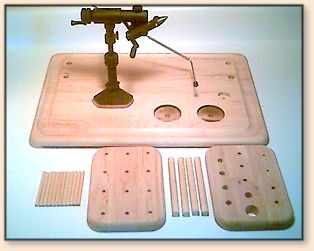

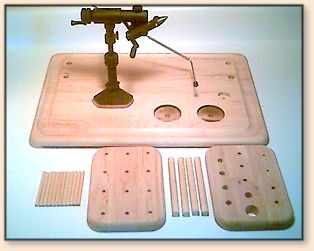

While checking out our local Big Lots discount store,

I found a nice selection of cutting boards. They were

well constructed and nicely finished maple. I picked

up a heavy 12" x 18" cutting board for a base for $9.00

and then selected two 5" x 7" mini cutting boards at $2.00

each to make thread and tool racks. On the way home I

stopped by the hardware store and purchased a ½" as well

as a ¼" wooden dowel.

First thing I did was to mount my vise on the large

cutting board. Many vises can be readily mounted on

your bench without using the clamping device. The

Danvise I use required only a ¾" hole through the

desired location on the bench to facilitate a clean

flush mount. Now I could position my tool and thread

shelves and insure adequate space around the vise for

tying. If your vise does not lend itself to bolting

to your base, you will first want to design your

clamping arm to position the vise in the desired

location. Make sure you consider height as well

as location and ample room for working around the jaws.

After positioning the shelves to suit me, I cut four

6" x ½" wood dowels to support them. I also cut twelve

3" x ¼" wood dowels as thread spindles. Using a drill

press and appropriate bits, I made holes for mounting

the shelves as well as holes for the thread rack spindles

and tools. Take your time and ensure that your tool

layout is comfortable for you.

Before mounting my shelves I took a 2 ¼" forstner bit and

drilled depressions near the front of my bench to keep

hooks, beads, and eyes from going adrift as well as a

depression to fit my ever present bottle of Sally Hansens

Hard as Nails. Then after first assembling the bench dry

to ensure fit, I reassembled it with glue and allowed it

to dry before proceeding. I took a brazing rod and bent

it to fit across the back of my tool shelves to provide

a drying rack for my flies. A piece of metal clothes

hanger would work as well. I also cut some 2mm foam to

fit the recessed depressions I had drilled in front of

the vice as well as four small pieces to glue on the

bottom corners to keep the bench from sliding or

scratching the desk top. When the glue was dry, I

rubbed in a coat of Minwax oil stain. You can leave

the wood natural, stain, varnish or whatever type finish

appeals to you. Just ensure that you remove any glue

from surfaces to be finished before it dries.

This bench suits my tying well. It may not suit your

style at all. This is provided not as a sporty-do-it-all

bench, but rather just food for thought for those

wanting a bench that best fits them and their budget.

The advantages of the cutting boards are obvious. They

are already laminated, cut and routed to shapes that

work well for the tying benches. They are constructed

of a durable hardwood, normally maple, and are quite

affordable. Many of them have a pronounced blood groove

routed around the outside edge which will prevent your

tying goodies from rolling onto the floor. My bench cost

$16.00 and took two hours to build and finish. While my

desk and backdrop are white and provide a good background

for tying, you could easily mount a piece of poster board

on your drying rack if needed for a brighter background.

Good luck! ~ Jim Hatch

|