|

Last May I had business in the Central New York area

and wanted to tempt some trout between work and sleep.

Being a semi regular in the Fly Anglers On Line Magazine

chat room I asked the Lady Fisher, Deanna Birkholm, if she

could put me in contact with a fellow from Cortland, New

York that I had chatted with some months ago about winter

fishing in the area.

She said she would be glad to help and told me the gentleman's

name was Comparadun, Leon Chandler. The name rang a bell but

didn't click with me. Deanna mentioned Leon had been a Vice

President of Cortland Line Company for over 30 years and that

he would most likely be able to point me to some good streams

in the area. A few minutes later I had his email address and

the Good Lady's endorsement.

I sent Mr. Chandler an email and invited him to lunch or dinner

to talk about the local fisheries. To my surprise he wrote

back and said to call him when I came to town and he'd

be happy to give me some guidance about the area fishing. He

also said that he could probably arrange a tour of the Cortland

Factory if I was interested.

Everything interests me. Especially fishing related subjects.

So I was pretty excited to get the chance to meet this fellow

and see how fishing line and fly lines are made. There aren't

too many fishing line manufacturers in West Virginia, except

for Dupont, and nobody there ever offered to show me how they

make line anyway.

Now, my curiosity is peaked and when that happens the first thing

I do is run a search on the Internet. I'm into Google Search's

right now because I like the way things come up there. Type in

Leon Chandler and you'll see these three Internet addresses:

www.flyanglersonline.com/features/readerscast/rc83.php;

www.wffj.org/chandler.htm ,

www.cortlandline.com/press_release.php

After viewing these web pages it became evident to me that this guy's not just

another retired manufacturing VP but America's Ambassador to Fly

Fishing no less.

I've been flailing water with fly lines since 1984 and I make the

effort to fish wherever I go and to go wherever there's fish. Most

of my fly-fishing education has come from a one-day beginner

course with a couple of my buddies after two years of living

in total ignorance. The rest of my meager knowledge came from

books, magazines, videos, trial and error and the wisdom derived

from five out of six Professional Guides I've fished with. I say

five out of six because the only thing one of the guides taught

me was to be choosier about guides. It's almost a daily exercise

reading, tying, and talking about fly-fishing but there's more

that I don't know then I do. I've come to the realization

that's the way its always going to be. The opportunity to learn,

first hand, from a man who has helped develop the modern fly line

over the past sixty years is something beyond my grasp normally.

I may be in over my head on this one but that's how I learned

to swim too.

So, I made the ten-hour drive to New York, and worked like a dog

for a week before I had the chance to schedule time to meet Leon

Chandler. My friend, Rick Greene, was with me on the trip and

late Saturday of the first week we stopped at the Cortland Line

Factory Store to buy our licenses and see what they had inside.

The Cortland Line Factory Store is located at 4053 West Road,

Cortland, New York. It's on the West side of New York State 281

just North of the intersection with New York State 222. It's

not a big store in the way of a Cabelas or L.L. Bean but a

comfortable sized fly shop or Pro Shop as Cortland conceptualized

and pioneered in the 1970's.

The shop had a sampling of all the Cortland line of products as

well as some good buys on discontinued items. The checkout

counter separated the fly-fishing and spin fishing sides. I

cruised the spin fishing side quickly and did my usual

micro-scan on the fly side. You could get everything you

need to get started, upgrade your equipment or just add to

your personal inventory of fly-fishing paraphernalia right

here in this shop.

It had the best selection of leaders I've ever seen on one

wall but of course it is Cortland. There were several racks

of rods from the affordable Cortland CL and GRF series that

had a very responsive feel when waggled and looked good too.

The Diamondback line is for the seriously discriminate angler.

These rods are in a class by themselves. The Classic Trout is

designed with a moderate action that brings feel back to casting.

I didn't waggle all the rods but man I wanted to.

There were representatives of all the Cortland reels including

the Embassy, Vista, Vista Turbine, Limited Edition Cortland Turbine

reels LTD, CLX, Crown, Magnum; the list goes on. I never realized

Cortland had so many reels. They also are featuring the STH

Series in partnership with the Argentinian manufacturer of these

high tech and innovative reels.

With all these goodies to look at and gush over the best part

about the shop was the guy who was running it. Joe Wegzyn

is the Store Manager and a great representative of Cortland

Line Company. He's been running the place for about five years

now and says it's growing every year. It's easy to see why.

Joe is eager to point you towards the fish, suggest the right

fly, and show you a neat way to tie a double mono leader for

pike instead of using a stiff wire leader. Besides turning us

on to some sparkle green nymphs that would prove to be deadly

on the stream closest to our hotel he came over after the shop

closed to see if we were having any luck. I've never had a

fly shop owner do that even after laying some considerable

dollars on the counter. Impressive guy.

I promised him not to divulge the fishing spot he sent us to

because he said it was the best kept secret in Cortland County.

I will say that if you like to catch lots of brookies and browns

in the 6" to 12" range and have a good chance to latch on to a

15" to 24" fish you might want to talk to Joe. Rick and I

fished for 2 hours that Saturday evening and caught and released

over 40 fish and at least 30 the next day in about the same amount

of time and never changed flys. True story.

The following Monday while driving down the road I remembered

I had better get in touch with Leon Chandler. I punched in

his number and after a few rings this deep gravely voice

says hello and I tell him who I am. He said Wednesday at

ten o'clock would be good for him and I mentally blocked

out Wednesday from 9:30 a.m. till 2 p.m.

On Wednesday I made my way over to 3736 Kellogg Road and turned

into the gate about five minutes till ten. You drive around to

the left of the big manufacturing complex to get to the front

office. Out front there are picnic tables set up for the

owner/operators of the Cortland Line Company and several people

were on break while enjoying the sunny day. It definitely looked

like an employee friendly place, as it should be, because all

the people who work at Cortland are also the owners. This in

itself is something to be proud of.

I spotted Leon Chandler tapping his pipe as I pulled up. I knew

what he looked like from one of the web sites that showed him

being inducted into the Freshwater Fishing Hall of Fame. I

parked and started towards the building. Leon had gone inside

so I asked one of the owners where I needed to go to meet him

and was quickly directed to the main office. Leon greeted me

as soon as I came through the door.

He had a firm handshake and looked me in the eye as we exchanged

names and pleasantries. Leon directed me into the reception area

where we sat down and he asked where I was from and about my

business in NY. I told him about my home and family and

explained the nature of my business and its progress over

the last week. He offered to buy me a cup of coffee and

we talked about the Cortland Line Company in the cafeteria

as different people came and went over the next forty minutes

or so.

He had a firm handshake and looked me in the eye as we exchanged

names and pleasantries. Leon directed me into the reception area

where we sat down and he asked where I was from and about my

business in NY. I told him about my home and family and

explained the nature of my business and its progress over

the last week. He offered to buy me a cup of coffee and

we talked about the Cortland Line Company in the cafeteria

as different people came and went over the next forty minutes

or so.

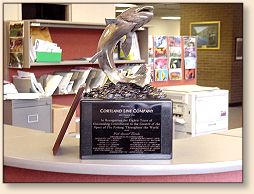

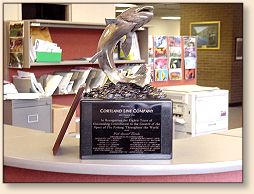

Ray Smith founded the Cortland Line Company in 1915. He was

an expert in braiding technologies of the day and designed

and produced a series of braided silk lines that propelled

Cortland into one of the leaders in the fishing line industry.

During World War II the Cortland Line Company put recreational

sports to the side and concentrated on producing parachute and

bomb cord. They researched and developed advanced manufacturing

technologies that contributed to the total effort to win the

big one. These new technologies were then transferred into

the fishing industry after the war.

Leon Chandler came from Missouri to visit some relatives in

1941 and started working at Cortland late that same year.

He stayed until his retirement in 1992 after serving as Vice

President for 30 plus years. Leon has been a witness to and

a big part of 60 years of growth and innovation at Cortland.

He has seen all the changes in ownership from the New York

City consortium that purchased the company from Ray Smith

and wasn't very fishing line savvy, to the ESOP that owns

and operates the company today.

Leon moved from the accounting department into marketing after

serving in WW II. He traveled all over the country promoting

the Cortland product line. Eventually, he got involved in the

overseas markets and has been to and fished everywhere except

some parts of Africa.

Because the Japanese market was not doing very well, Leon went

there and put on some exhibitions to promote the sport of

fly-fishing and Cortland's lines. The Japanese market for

fly-fishing was estimated at 300 anglers before Leon went

over. Now there's an estimated 200,000 fly fishermen in

Japan and all of them know Leon on sight, as he's been

back seven times since then.

You can read about the history of fly line development in

Leon's article on Fly Anglers On Line Magazine. It's in the

archives of Readers Casts under features and it's a very

interesting and informative piece.

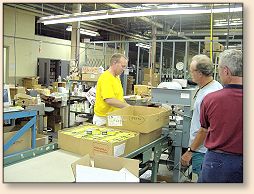

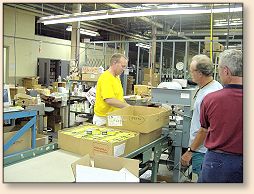

When our cups were empty Leon led the way into the heart

of the Cortland Line Company where lines are braided, wound,

extruded, dyed, mixed, matched, tested, spooled and packaged.

In the same facility reels are assembled, rods repaired and

matched and balanced Fly Fishing packages are put together.

The plant was not running at full capacity the day I was there

so they could do the year-end inventory. As we walked through

the door of the cafeteria into the main braiding area we were

met by a whirring and clattering sound of what had to be a

thousand or so braiding machines (actually about two thousand)

that were continuously turning and winding huge spools of

multifilament yarn into the hundreds of different trolling,

fishing, running and backing lines that Cortland makes. These

machines run 24/7 normally. It was a little overwhelming at

first with all the machines turning spindles of multifilament

yarn in synchronized motion into specific sized lines.

Two types of multifilament yarn are used for two different

purposes: Nylon and Dacron (polyester). The Nylon is used

for making braided nylon bait casting lines, fly line backing

and fly line core stock. The Dacron creates deep-sea trolling

lines because it has less inherent elongation (stretch) than

does nylon.

Two types of multifilament yarn are used for two different

purposes: Nylon and Dacron (polyester). The Nylon is used

for making braided nylon bait casting lines, fly line backing

and fly line core stock. The Dacron creates deep-sea trolling

lines because it has less inherent elongation (stretch) than

does nylon.

Leon said some the spools that were still in use had been

there before he came on board and Leon retired in 1992 after

fifty years with the company. What was amazing to me was

all the intricate parts of the braiding machines and how

they were calibrated and maintained to certain tensions and

speeds that created the product Cortland would deem perfect

enough to sell to the consumer.

The biggest question that came to mind was who was the guy

(or gal) that figured out how to make all this stuff work

in the first place. Not being very mechanical, it all seemed

too big a mind bender for my feeble brain to comprehend. But

there they were, all working away like little troopers,

spinning out yard after yard of braided monocord and such.

We then went into a dye room where about 16 separate lines

were being unspooled and loaded onto a dying apparatus,

called a Rube Goldberg contraption (named for Rube Goldberg)

that would color trolling line in ten-yard increments so

that you can tell how deep you are trolling. After the

braided line has been despooled and loaded on the dying

machine the operator switched directions and these metal

pans containing all different colored dyes would raise up

in sequence, at just the right time, as the line passed

through each pan in order to dye the line in multicolored

order. Under the pans the floor looked like a huge tie-dyed

T-shirt. It was a pretty neat thing to see.

We then went into a dye room where about 16 separate lines

were being unspooled and loaded onto a dying apparatus,

called a Rube Goldberg contraption (named for Rube Goldberg)

that would color trolling line in ten-yard increments so

that you can tell how deep you are trolling. After the

braided line has been despooled and loaded on the dying

machine the operator switched directions and these metal

pans containing all different colored dyes would raise up

in sequence, at just the right time, as the line passed

through each pan in order to dye the line in multicolored

order. Under the pans the floor looked like a huge tie-dyed

T-shirt. It was a pretty neat thing to see.

They were making lead core trolling lines called KERPLUNK.

Every 10 yards the color changes and each line comes with

a label that explains the color sequence so an angler can

tell how much line is played out by the color of his reel

spool. It's one of those simple yet ingenious ideas.

In the next room Leon showed me how they make monofilament.

The whole apparatus is called a Monofilament Extruder and it

works like this: On one end of the area was a rectangular

tin about the size of a 2.5-gallon gas can. It was fastened

in a mixer that turned the can over and over making the base

for the monofilament in order to get the color and type of

line they wanted to make. This mix of base material was

then fed into a hopper and the granules were heated into a

liquid then forced under pressure through a nozzle like a

showerhead while in a semi liquid state. About 8 lines are

then arranged on a set of pulleys as they are pulled through

a tub of water that cools the product before it goes through

a series of wooden tensioners that ultimately pull and stretch

the pliable monofilament into the diameter and test strength

of the batch they are running.

Leon handed me a length of monofilament (known as un-oriented

because it hadn't been stretched yet) before it is stretched

and told me to pull it apart as far as I liked. I had about

a foot of line between both hands and pulled as far as my arm

span would accommodate. The line got thinner and thinner

until I quit applying pressure. When I stopped pulling the

molecules in the line set up and I couldn't stretch the line

any more. That's how the machine works. As long as constant

tension is applied the monofilament lengthens and the diameter

reduces up to the point that the tension stops, thereby making

it oriented as the final product. The result should be the

size and test that the batch was designed to be. There's a

quality control person who tests every 6th batch and if the

line doesn't meet Cortland's exacting standards its recycled

and reprocessed.

There's a room where the owners assemble the STH Reels and

repair rods. They all looked pretty busy and we didn't bother

them too much. Leon told me the STH Reels are assembled in

Cortland from parts made in Argentina. The manager of the

assembly operation is Juan Sacconi an Argentinean and the

son of the STH owner Robert Sacconi. Cortland is the

distributor of the reels in the US and Canada. STH distributes

to the rest of the world.

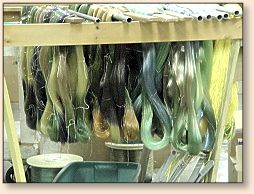

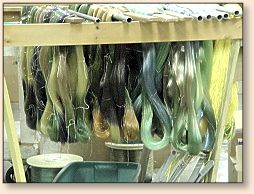

Leon then showed me where they dye skeins of lines that become

the core of fly lines. They had a new type of machine that

Leon hadn't seen in operation before but he said it was

supposed to be more efficient then the regular system.

Innovation and technology development are what keeps a

company like Cortland on the leading edge of the industry.

Leon then showed me where they dye skeins of lines that become

the core of fly lines. They had a new type of machine that

Leon hadn't seen in operation before but he said it was

supposed to be more efficient then the regular system.

Innovation and technology development are what keeps a

company like Cortland on the leading edge of the industry.

We didn't see the process that Cortland uses to apply the

tapered coating of the fly line. This is a closely guarded

trade secret and very few people are allowed in the area

where this is performed. Leon told me that the outside

coating is made up of a PVC containing millions of microscopic

glass beads that are hollow and trap air. The line floats

because of the air in the glass beads. The formulation has

to be precise so that there is enough buoyancy and enough

diameter to allow them to cast well.

The fly lines are then formed into single tapered, double

tapered, rocket head and all the other configurations that

Cortland uses to make the 350 different fly lines that are

on the market today. When the lines are processed they come

out in one continuous length that have to be cut into

individual lines. These spools are pulled through a counter

and through the fingers of some ladies with extra sensitive

feel to check for imperfections. These ladies inspect every

inch of the fly line and are thoroughly experienced at what

they do. Leon informed me that one lady, who had retired

shortly before my visit, worked for 35 years as an inspector.

"It is interesting to speculate where all the fly lines

went - and people who used them - that had passed through

her fingers during the 35 years," Leon later told me.

While on a steelhead fishing trip in Michigan the prior April

I had to strip 40 to 50 feet of line through my fingers all day.

After about the tenth time, I realized I was going to cut a

groove in my stripping finger if I kept this up for eight

hours so I put on a couple of Band-Aids to ward off the cuts

and blisters. By the end of the day the Band-Aid was ripped

to pieces and barely hanging on.

I asked the lady who was checking the line how she kept that

from happening and Leon had her show me her finger. She said

there was a foot-operated brake that stopped the line where

she needed to cut it but some times she forgot to use the brake

before she clamped down tight on the line. Her fingers showed

the result of forgetting to use the brake in the crease of the

first joint of the index finger. She said you don't do that

too many times before you learn not to grab the line too soon.

If these quality control experts feel any flaws in the line

it is removed and labeled imperfect. I asked what the percentage

of imperfect lines was and Leon said it was very low considering

the number of lines produced every year. I also asked if the

imperfect lines were sold at a discount and Leon informed me

that Cortland will not sell any line that does not meet it's

exacting standards and that they feel the public deserves only

Cortland's best product and nothing inferior is ever sold.

That's the reason their lines aren't discounted. They do,

however, pass on some of the imperfect lines to their pro

shops for demonstrations and promotional use.

If these quality control experts feel any flaws in the line

it is removed and labeled imperfect. I asked what the percentage

of imperfect lines was and Leon said it was very low considering

the number of lines produced every year. I also asked if the

imperfect lines were sold at a discount and Leon informed me

that Cortland will not sell any line that does not meet it's

exacting standards and that they feel the public deserves only

Cortland's best product and nothing inferior is ever sold.

That's the reason their lines aren't discounted. They do,

however, pass on some of the imperfect lines to their pro

shops for demonstrations and promotional use.

Leon is a great believer in cleaning your line before every

outing. He explained that there's always dirt, pollen and other

small particles in the waters film that cling to your line and

after a while the buildup will counteract the buoyancy of the

fly line and adds to the disturbance on the water when you lift

it for your next cast. Every Cortland Fly Line comes with a

little cleaning pad and Leon suggests we use them, regularly,

to maintain the lines floating capabilities.

Our next stop was with a lady who was putting together some

kits for beginners that were earmarked for a youth camp

somewhere that Cortland supports. Cortland also was one

of the pioneers in offering Balance Fly Rod Outfits,

complete with rod, reel, line, leader backing, and in

later years an instructional video. I've watched this

video numerous times with friends and I must say its one

of the best ones I've seen as a way to introduce a

new-comer to the sport.

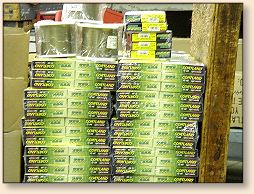

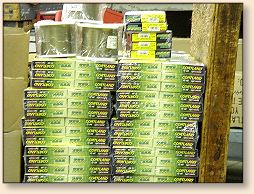

Adjacent to this was the stock room area where all the

different products are shelved and orders are filled and

shipped. As with all manufacturers there's a fine line

between having too little and too much inventory on hand.

Over the years the people at Cortland have developed a

system that anticipates demand and they try to have enough

of their products on the shelf, ready to go, at the right

time. If this area were a fly shop it would have the most

complete array of fly fishing lines, reels and rods you've

ever seen.

Adjacent to this was the stock room area where all the

different products are shelved and orders are filled and

shipped. As with all manufacturers there's a fine line

between having too little and too much inventory on hand.

Over the years the people at Cortland have developed a

system that anticipates demand and they try to have enough

of their products on the shelf, ready to go, at the right

time. If this area were a fly shop it would have the most

complete array of fly fishing lines, reels and rods you've

ever seen.

Our tour was coming to an end and my head was swimming trying

to file away all the information that I had been exposed to so

I could tell my fishing buddies what I had learned. Leon asked

me what size rod I used and preceded to give me four rolls of

Lazer Line to try out. One roll was a Nymph Tip Line that Leon

held the patent on before it expired. I can't wait to put that

one on and see how it works. Of course he also gave me some

line cleaning pads to keep them in good shape. As much as I

fish, and with a thirteen year old son who never passes up

the chance to come with me, these lines will be put to good

and frequent use.

We sat back down in the cafeteria and Leon showed me some places

on my map to fish on the Beaver Kill and Delaware Rivers, just

an hour and a half away from Cortland. I've wanted to try these

streams ever since I started reading about fly-fishing, but I

never got the chance to go to these rivers over the next two

weeks that I was in the area. I guess I'll have to make a

return trip later this fall to try these fabled streams, and

maybe I can get Leon to come along.

Altogether, this trip to New York turned out to be uncommonly

fortuitous to my business interest and especially gratifying

to my fly-fishing interest. Having met some of the dedicated

people like Leon Chandler, Joe Wegzyn, and all the other

owners who strive to produce a superior product, I've gained

a newfound respect and admiration for the company and the

people who make it work at the Cortland Line Company.

~ Bo Ranson

|

He had a firm handshake and looked me in the eye as we exchanged

names and pleasantries. Leon directed me into the reception area

where we sat down and he asked where I was from and about my

business in NY. I told him about my home and family and

explained the nature of my business and its progress over

the last week. He offered to buy me a cup of coffee and

we talked about the Cortland Line Company in the cafeteria

as different people came and went over the next forty minutes

or so.

He had a firm handshake and looked me in the eye as we exchanged

names and pleasantries. Leon directed me into the reception area

where we sat down and he asked where I was from and about my

business in NY. I told him about my home and family and

explained the nature of my business and its progress over

the last week. He offered to buy me a cup of coffee and

we talked about the Cortland Line Company in the cafeteria

as different people came and went over the next forty minutes

or so.

Two types of multifilament yarn are used for two different

purposes: Nylon and Dacron (polyester). The Nylon is used

for making braided nylon bait casting lines, fly line backing

and fly line core stock. The Dacron creates deep-sea trolling

lines because it has less inherent elongation (stretch) than

does nylon.

Two types of multifilament yarn are used for two different

purposes: Nylon and Dacron (polyester). The Nylon is used

for making braided nylon bait casting lines, fly line backing

and fly line core stock. The Dacron creates deep-sea trolling

lines because it has less inherent elongation (stretch) than

does nylon.

We then went into a dye room where about 16 separate lines

were being unspooled and loaded onto a dying apparatus,

called a Rube Goldberg contraption (named for Rube Goldberg)

that would color trolling line in ten-yard increments so

that you can tell how deep you are trolling. After the

braided line has been despooled and loaded on the dying

machine the operator switched directions and these metal

pans containing all different colored dyes would raise up

in sequence, at just the right time, as the line passed

through each pan in order to dye the line in multicolored

order. Under the pans the floor looked like a huge tie-dyed

T-shirt. It was a pretty neat thing to see.

We then went into a dye room where about 16 separate lines

were being unspooled and loaded onto a dying apparatus,

called a Rube Goldberg contraption (named for Rube Goldberg)

that would color trolling line in ten-yard increments so

that you can tell how deep you are trolling. After the

braided line has been despooled and loaded on the dying

machine the operator switched directions and these metal

pans containing all different colored dyes would raise up

in sequence, at just the right time, as the line passed

through each pan in order to dye the line in multicolored

order. Under the pans the floor looked like a huge tie-dyed

T-shirt. It was a pretty neat thing to see.

Leon then showed me where they dye skeins of lines that become

the core of fly lines. They had a new type of machine that

Leon hadn't seen in operation before but he said it was

supposed to be more efficient then the regular system.

Innovation and technology development are what keeps a

company like Cortland on the leading edge of the industry.

Leon then showed me where they dye skeins of lines that become

the core of fly lines. They had a new type of machine that

Leon hadn't seen in operation before but he said it was

supposed to be more efficient then the regular system.

Innovation and technology development are what keeps a

company like Cortland on the leading edge of the industry.

If these quality control experts feel any flaws in the line

it is removed and labeled imperfect. I asked what the percentage

of imperfect lines was and Leon said it was very low considering

the number of lines produced every year. I also asked if the

imperfect lines were sold at a discount and Leon informed me

that Cortland will not sell any line that does not meet it's

exacting standards and that they feel the public deserves only

Cortland's best product and nothing inferior is ever sold.

That's the reason their lines aren't discounted. They do,

however, pass on some of the imperfect lines to their pro

shops for demonstrations and promotional use.

If these quality control experts feel any flaws in the line

it is removed and labeled imperfect. I asked what the percentage

of imperfect lines was and Leon said it was very low considering

the number of lines produced every year. I also asked if the

imperfect lines were sold at a discount and Leon informed me

that Cortland will not sell any line that does not meet it's

exacting standards and that they feel the public deserves only

Cortland's best product and nothing inferior is ever sold.

That's the reason their lines aren't discounted. They do,

however, pass on some of the imperfect lines to their pro

shops for demonstrations and promotional use.

Adjacent to this was the stock room area where all the

different products are shelved and orders are filled and

shipped. As with all manufacturers there's a fine line

between having too little and too much inventory on hand.

Over the years the people at Cortland have developed a

system that anticipates demand and they try to have enough

of their products on the shelf, ready to go, at the right

time. If this area were a fly shop it would have the most

complete array of fly fishing lines, reels and rods you've

ever seen.

Adjacent to this was the stock room area where all the

different products are shelved and orders are filled and

shipped. As with all manufacturers there's a fine line

between having too little and too much inventory on hand.

Over the years the people at Cortland have developed a

system that anticipates demand and they try to have enough

of their products on the shelf, ready to go, at the right

time. If this area were a fly shop it would have the most

complete array of fly fishing lines, reels and rods you've

ever seen.