|

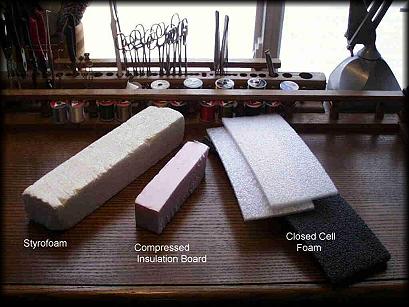

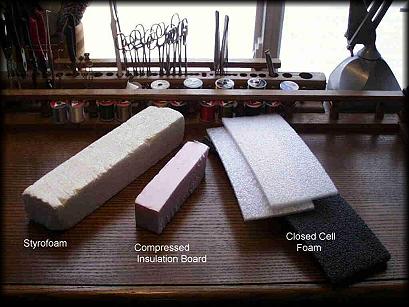

Foam. Foam is a very popular material used in making poppers. It is light in

weight, very easy to work with, inexpensive, comes in a variety of forms and

minimal tools are needed in their production. There are a couple of cautions

when using foam you need to be aware of. It is very reactive to certain

adhesives and paints. In other words, if the adhesive or paint contains ethyl

alcohol, mineral spirits, or acetone additives (usually used as a thinner or

evaporative agent) it will melt the foam into a jelly like mass on your work

surface. I generally use 2 part epoxy for adhesive or filler and either

acrylic or latex based paints just to be safe. Some of the foam materials I

use and their assets and drawbacks are listed below:

Preformed: Preformed popper shapes can be purchased from various catalog

vendors (Cabela's, Stamina (out of Minneapolis, MN), Netcrafters (out of

Ohio)). These are preformed, pre-shaped, and, sometimes, the hook slots are

already cut into them. Minimal work needs to be done to get to the finished

product. The drawbacks are they only come in certain sizes or shapes, usually

1/2" to 3/4" and cone shaped.

Foam Injector Systems: These can be purchased through catalog sources also.

They consist of 2 part mixes of chemicals to create the foam, an injector, and

a set of molds. You mix the chemicals together, place it into the injector

and inject the foam into the mold. I don't own one but do know several people

who have tried them, most were not happy with the results. But it is an

option out there, especially if you want to get into some heavy-duty

production and can get the consistency and method down to a science.

Closed Cell Foam: Closed cell foam can be picked up at a lot of places. It

can be purchased at hobby and craft stores in sheets and dowels. You can

find it in boxes, used as packing material. You can find it at construction

sites (especially roadwork) that are pouring concrete being used in the

expansion joints. It's also sold in 'ropes' at many contractor supply houses

and chain stores. It can be painted (though the paint will chip off) but

waterproof magic markers work great for coloring and details. Simply cut off

the amount and shape you need using a razor blade or Exacto knife, thread the

hook through it (or tie or glue the hook onto the piece), detail it with the

magic markers, add a few feathers or rubber legs and you've got yourself a

popper! It comes in a wide variety of colors so have fun and be creative.

Foam Insulation Board: Yes, you know what I'm talking about, the stuff they

use to insulate houses. It comes in 4 foot by 8-foot pieces

for a couple of dollars at most home improvement centers. There are also a

variety of densities, colors and thicknesses to choose from. The easiest way

to avoid having to by a full sheet is to find a construction site and ask if

you can pick up a few scraps around the site. Most of the time the contractor

will be vary accommodating, especially if you offer to make him a few also.

It is most often used around the outside of basement walls and put on just

before it is back filled. The foam board is very easy to work with. It can

be cut and shaped with a razor blade or Exacto knife, the hook placed into it,

painted and finished in a couple of hours. (Hint, don't try to force your way

through the material with the blade, it will crush and tear, slice the

material with a sharp blade).

"Canned" (Liquid) Spray Insulation: Most of you know this stuff. It comes in

a can, you shake it up and spray it into cracks and crevices and it expands

(and expands, and expands. . .) to fill the gaps. Please note that there is now a

water-soluble type (or latex based) out there and, while it's great for

insulation purposes, it won't work for this application. You want the

regular kind, it's yellowish in color and sticky and you can't wash it off

anything without using gas or mineral spirits. A can only costs around $4.00

(I watch for sales) and you can always find an area of your house that needs a

little repair. The thing is, once you start a can you might as well use it

all because trying to get the nozzle clean enough to use the rest is nearly

impossible. What I do is lay out a few sheets of wax paper and spray the

'left over' in lines on the paper. Let it dry for a couple of days, cut off

chunks with a sharp blade and shape it into poppers. I also go around the

different areas I filled and cut off the excess and us it also. Once

dry, this stuff can be painted, sanded (carefully), filled, glued, etc. Just

remember the rule of not using petroleum products, paints or solvents.

Spun Deer Hair. Deer hair is hollow, like a paper straw, as is the hair on

some other animals such as elk and moose. It comes in a wide variety of dyed

colors, along with the natural colors. 'Spinning' the hair is almost an art

form in itself and does take some time and lots of practice to learn, but once

you learn it, the variety of poppers you can produce increases dramatically.

Spun hair poppers and lures have been around for probably several hundred

years (or more). The process basically involves placing a small bunch of hair

on the hook, wrapping a rather loose first turn of thread around the hook and

hair, then a series of gradually tighter loops. In the process, the hair will

flare out, like a fan, and in the winding process, rotate or 'spin' around the

hook. That bunch is then pushed into position and another group is put in

place. This process is repeated until the hook is covered with a tight mass

of spun hair. Then the fun begins. Using a scissors or razor blade, start

trimming this big hairball into a shape that resembles something real. You

can make frogs, mice, poppers, the limit is only your imagination. Once you

get good at it, you can start combining colors for special effects and color

blending. For those of us who have done this, I realize this is a bit over

simplified, but essentially that's what happens.

Miscellaneous Materials: There are many other materials that can be used in

making popper bodies such as wool, yarn, cotton, and rubber. Almost anything

you can think of that will float on the surface of the water can probably be

adapted in one way or another. I know of one guy who used plastic soda straws

from a fast food place, cut them into two inch pieces, ran a piece of

monofilament line through them, tied a hook on the end. He used a nail head,

heated with a lighter to carefully seal the ends of the straws (without

melting the mono) so they would hold air. He then painted it dark green on

top with a light colored "belly", put a couple of yellow stripes down the top

side and calls it a garter snake. The design is so simple and it works great

for large mouth bass and northern pike. Plus the materials are practically

free.

Ok, so now you have materials. Hopefully next week we'll start building a few

poppers. I'm going to skip the pine and use basswood. The procedure is about

the same for both and I'll actually use the basswood popper. Until then, go

fish!

~ Randy Fratzke

|