Bob Summers:

fly rods and realities

By Greg Frey

While many people grudgingly accept the

reality of our society's work structure, a unique few make their own

reality. Bob Summers may be best known for creating some of

of the world's finest bamboo fly rods, but in doing so, his greatest

creation has been the life he has made for himself.

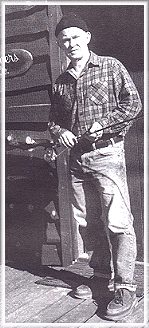

I entered Summers' world for a few hours on a bright March morning.

He wore a Navy watch cap, flannel shirt and jeans that had seen

many days in front of lathes, presses and mills. We talked while his

small terrier, Sam, vied for attention by nudging my hand and showing

off his array of chewing toys.

Unlike most anglers whose dens flaunt pictures of fat fish, Summer's

office walls were covered by old photographs of rod builders such as

Jim Payne, Morris Kushner and Lyle Dickerson. There was also an

enlarged National Geographic photograph of workers harvesting cane

in China. With a constant backlog of 60 to 70 rod orders on his desk,

Summers seemed content with his business. But his modest home

and lifestyle on the Boardman River near Traverse City, Mich.,

certainly don't tell the true story of his success among rod builders.

Unlike most anglers whose dens flaunt pictures of fat fish, Summer's

office walls were covered by old photographs of rod builders such as

Jim Payne, Morris Kushner and Lyle Dickerson. There was also an

enlarged National Geographic photograph of workers harvesting cane

in China. With a constant backlog of 60 to 70 rod orders on his desk,

Summers seemed content with his business. But his modest home

and lifestyle on the Boardman River near Traverse City, Mich.,

certainly don't tell the true story of his success among rod builders.

If one believed in destiny, it would be easy to see what Summers

was destined to become a rod builder. He was raised on the west

side of Detroit and began fishing at the age of four. By 12, he

was tying his own flies and fishing planted trout near Northville.

At age 15, Summers was a known tying-materials customer in

Paul Young's fly shop. At the time, the Young shop was a retail

store where fishing equipment, tying materials, boats and Evinrude

motors were sold. A workshop was set up in the back for building

rods. When the time came to find an after-school job in 1956, Summers

knew where to look. Young's shop was to be moved closer to Summers'

neighborhood. His timing couldn't have been more perfect.

"Some kids went and worked in the grocery shore," Sommers said.

"I worked there. My first job was to remove thread from glued-up

sticks. The I began filling. Before you knew it, I was involved in

all parts of the rod building." Rod building wasn't the only thing

Summers learned to do at Young's shop. In the 18 years he worked

there, he sold boats and was sent to the Evinrude outboard factory to

learn to become a mechanic. He also learned to sew. His first sewing

job was to make a flat creel from woven rice grass placemats. "We

used to sell them for about $7.95 without a strap. I just sold one for

$100 because now they're collectable."

Upon meeting Summers, it doesn't take long to perceive his meticulous,

precise nature. Young's rod-building shop gave him an outlet for that

precision. "Right away I used to do things a little more meticulous than

they were doing," Summers said. "The feet on the guides - Mr. Young

never ground them off. The feet would be sticking out beyond the wraps.

The first time I did one, I took and filed it. He said, "What are you doing?"

I said, 'It would be a little easier to wrap over this and do a neater job.'"

To this day, that's one of the ways to tell a Young rod built by Summers.

That and the handwriting of course. Paul Young, Sr. died in the spring of

1960, leaving Summers and Jack Young as the builders of Young rods.

Summers continued working and the company continued to flourish under

the leadership of Paul Young's wife, Martha. Mrs. Young managed the

business until she retired and it was moved to Traverse City.

"Mrs. Young was always the backbone of the business. She kept

everything together," Summers said. "But in 1969, we (The Young

shop) moved up to Traverse City. Without Mrs. Young in the picture,

things didn't seem to survive. So I left to carry out my own ideas."

~ Greg Frey

Continued next time!

This article is excerpted from the July/August issue of

Midwest Fly Fishing.

We thank them for use permission.

|