| |||

|

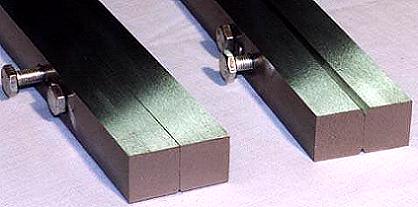

The planing form consists of two parallel steel bars with a sixty-degree groove

running between the two bars along the length of the tool. One side of the

form has a relatively deep groove for forming large strips for butt sections;

the other side has a shallow groove for forming tip sections. It should be

noted that a typical rod tip may measure only about .060 inches, and therefor

an individual tip strip is a mere wisp of bamboo measuring about .030 of an

inch! The sixty-degree groove is tapered- it becomes progressively deeper from

one end of the form to the other. In addition, the depth of the groove in the

planing form can be adjusted by means of screws that push or pull the forms

apart or together. These adjustment screws are located every five inches

along the form's length and correspond to the convention of rod tapers being

determined at five-inch intervals.

|

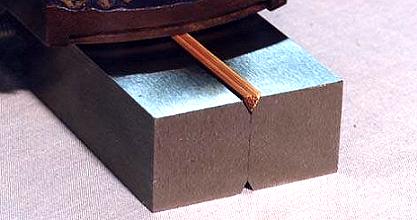

The equilateral form of the strip conforms to the shape of the groove. The hand plane is then used to shave off the excess cane above the surface of the form. Once the strip has been planed down to the surface of the form, the size of the strip is a mirror image of the depth that has been set in the form. The tapered strip is now referred to as a spline. This process is then repeated to plane the taper into the five remaining strips.

© 1999, J.D. Wagner, Inc.

|