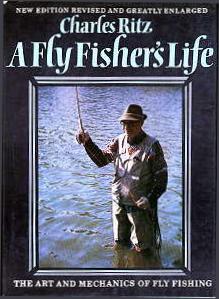

The Split Cane Fly Rod

(Excert from Part III: Research and Technique)

A Fly Fisher's Life (1959)

By Charles Ritz

Our sincere thanks to Crown Publishing Company

September 7th, 1998

Publishers note: Since this

publisher is older than dirt, it occured to me that some may never have

seen many of the older books. From time to time, we hope to

excerpt interesting segments from our personal library to enlighten,

entertain and perhaps amaze our rod building friends. Some things

are older than you might think. Most of these books are long out

of print, and if we spark an interest in you, check out the used

book stores, or one of the mail-order book sellers. Armchair Angler

in Hillburn, NY is one we particularly like. We previously

ran a series on bamboo from Ring of the Rise, (check the archives)

which I understand is now available in reprint. Your suggestions

and comments are always welcome.~DB

Publishers note: Since this

publisher is older than dirt, it occured to me that some may never have

seen many of the older books. From time to time, we hope to

excerpt interesting segments from our personal library to enlighten,

entertain and perhaps amaze our rod building friends. Some things

are older than you might think. Most of these books are long out

of print, and if we spark an interest in you, check out the used

book stores, or one of the mail-order book sellers. Armchair Angler

in Hillburn, NY is one we particularly like. We previously

ran a series on bamboo from Ring of the Rise, (check the archives)

which I understand is now available in reprint. Your suggestions

and comments are always welcome.~DB

The Split Cane Fly Rod, Part Four

(Excerpt from Part III: Research and Technique)

"Malformation, Weakness"

"Since bamboo is a plant, the best processes

of manufacture cannot change its basic texture. Very careful

selection can eliminate wood which has not the appearance of

guaranteeing the good quality of fibre necessary for the

manufacture of split bamboo. But this quality can only finally

be confirmed when, the rod having being completed after being

tested for curve, the fisherman tries it out on the water.

A length of split bamboo is comparable

to the leaf of a steel spring as far as elasticity and the

breaking limit are concerned. To be constantly demanded from

a rod the maximum it can give quickly brings on fatique which

is transformed into permanent and more or less serious

malformations. The same thing happens to a rod after long

service. In spite of all the care lavished on it, it will

show signs of weakness in curvature. There is a decadence in

the stamina of the wood, precisely as there is in that of

the steel of a spring.

The malformation of a rod tip is but

rarely due to a failure of the glue. The glues used today

have the effect of soldering the six strips together. In

general, a failure of this kind is due to a slipping of the

fibres which partially detatch themselves from the material

sealing them together. A super-quality rod will become malformed

if it is kept continuously bent for several hours, even if the

curve is not more than half its maximum flexion. After several

hours in a normal position, it will ultimately straighten out

again and will not revert to its malformation while fishing.

The fibres will have returned to their normal position.

In certain hands, rods will live longer

than their owner, while other people will spoil them

quickly whatever the quality of the rod may be. This is

due to a twist of the wrist while casting or to defective

holding of the rod when endeavouring to bring fish to the

net. Too many rod tips are killed in this way.

Any failure of the glue is generally

owing to shock and torsion either due to the style of casting

(the thumb along the side of the handle instead of on top of

it), or by taking the rod apart by twisting (this applies to

rods not taken apart at night). I always disjoint my rods

after every day's fishing. A slight rod deformation towards

the butt of the rod is normal because the maximum casting

power is applied in the last forward cast."

~Charles Ritz

Next time,"How I began working with split bamboo."

|