Bamboo Chat- Host RON KUSSE - Thurs. 5-8 p.m. PST (8-11 EST)

|

Preparing Cane Strips and the Thickness PlannerBy Ron Kusse, Master Rod Maker

|

|

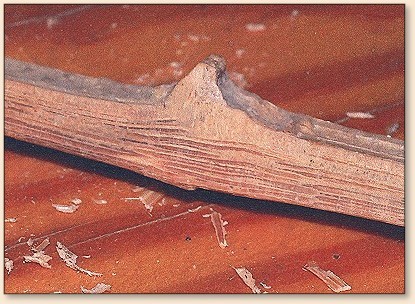

This is a strip of thick wall cane. It actually mics about .370 between nodes. You can see where the interior dam was knocked out and on the other side of this is the node itself. The way I prepare my strips is the same as it was done by the Payne Shop and the Leonard Shop. The cane pole is split in half so that the split will follow the grain of the cane. A guide is then set on the table saw with the proper distance for the width you want to cut the strip. You press the split part of the strip against the guide and push it through the table saw. In sawing the strip keeping the split edge against your guide will insure the cut will follow the grain of the cane. The following photos and captions will show how in this shop this prepares the strip to be put through the miller without any strain on the machine by taking up more material than is absolutely necessary.

|

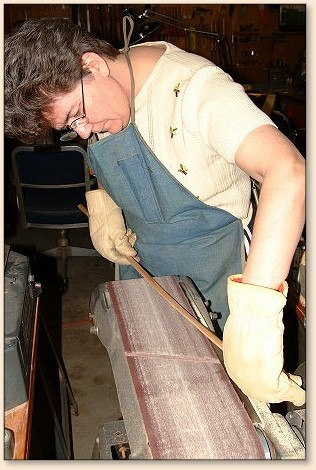

Caroline is using the 6 X 48 inch belt sander to sand the interior dams down to the level of the rest of the strip. Until this is done you cannot press or file your exterior nodes. |

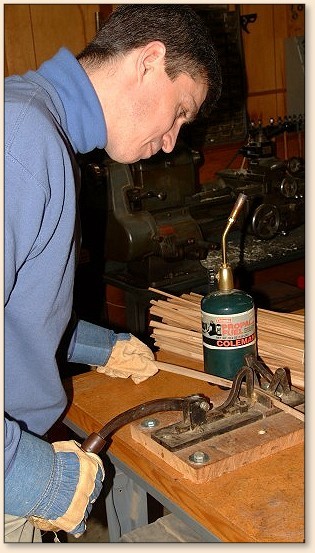

Ray is pressing the nodes in the node presser. After he has pressed the nodes he will straighten the strip using his hands and occasionally using the node presser. The propane torch is used to heat the strip so it will bend and stay in place without cracking or splitting during pressing nodes and straightening.

|

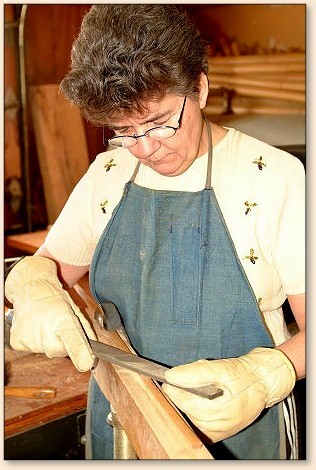

Caroline is filing the nodes with a 14 inch mill bastard file. When she is finished the best way to check a node after it is filed is by running your bare finger over the area of cane where the node was. If you can't feel where the node was it probably is good.

|

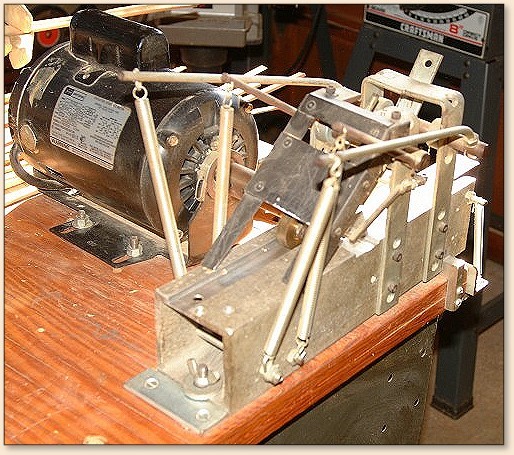

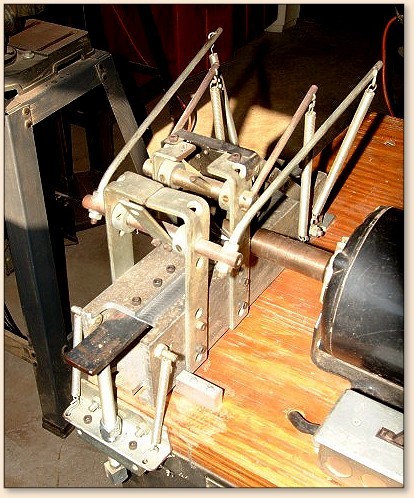

This is the thickness planner photo taken from the exit end of the planner where the cane strip emerges after being sized. The spring and cantilevers are used for the two hold downs before and after cutter.

This is a view of the cane feed end (entrance) of the thickness planner showing the hold down to keep the cane flat against the bed and the adjustment for thickness. The hold down pressure is about 30 pounds.

|

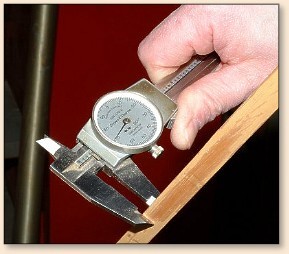

Ray is micing the strip before putting it through the thickness planner. It actually mics out at .370. With one pass through the thickness planner it will be reduced to a very precise .220 the entire length of the strip with less than one thousands variance. |

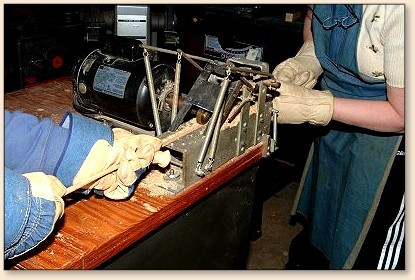

The thickness planner in operation. This is a push pull machine. Caroline is feeding the strip into the machine under the cutter and Ray is pulling the finished strip from the other end.

|

Here are some strips that have been put through the thickness planner. There are four strips at .220. There are four narrower strips at .115 and then there is one strip that was put through to see how thin we could make it through with precision and that one is .045. All strips were within one thousands of each other according to what the machine was set for and the planned surface is actually a polished surface. ~ RK

|