What's all the Hoopla about Cane Fly Rods?

By R.L. "Bob" Nunley, Rodmaker

Of late, there has been a lot of discussion about bamboo

fly rods, what they are, why people like them and how they

are made. Well, I've got my bulletproof vest on and ready

to make my opinion known, so fasten your seatbelts, and

get ready for the ride!

First off, there have been questions about what a good cane

fly rod actually is. Well, in my opinion, it's a finely tuned

casting machine that looks like a million dollars. A cane fly

rod, as I've mentioned in a previous article, is not only a

fine fishing instrument, but also a potential heirloom.

Now, what makes a fly rod an heirloom? Part of it is who makes

it! I mean, a rod made by Joe Rodmaker who nobody has ever heard

of may fish well and it may be a beauty, but that doesn't mean

it will be collectable someday. What makes collectability?

First, the maker has to pay his dues. By that, I don't mean he

has to work through years of apprenticeship or have been tutored

by one of the past or present day Masters of the craft. I mean

he has to commit his life to the making of a fine cane rod.

Much has been said about the heart of the rodmaker, but in my

opinion, heart has nothing to do with it. Relationships to cane

rods may be an affair of the heart, but the making of a fine cane

rod, while it may be a passion, has more to do with talent,

perseverance and commitment. I know there are very few rodmakers

out there who can just quit their "day job" and start making rods

for a living, and that's not what I'm talking about. I'm talking

about being committed to working into the wee hours of the morning

to make the perfect rod. I'm talking about not being able to accept

an uneven or gapped wrap. I'm talking about not being tolerant of

even the slightest flaw in the varnish. I'm talking about committing

your life to your craft.

These flaws, or lack of them, are what sets the trade rods, or

even inferior custom rods apart from a true custom fly rod. Many

of the production companies of the past, such as Montague,

Horrocks-Ibbotson, the companies that mass produced rods in

Occupied Japan after World War II, and a few others, did make

inferior rods, but not all of their rods were inferior. For

instance, Horrocks-Ibbotson had three very fine casting, very

finely outfitted two-piece rods, the Tonka King, Queen and Princess.

Montague, after acquiring the Thomas Chubb Rod Company in 1890,

continued to make Chubb rods in their Post Mills, Vermont factory

until 1932, and these were considered some of the finest rods of

their time. From time to time you'll even fine one of the Occupied

Japan rods that casts like a dream. Did these compete with the

better rods of the day, like the Leonard, Payne, and F.E. Thomas

rods?

No, they couldn't compete with the Leonard's whose rods

were made on more 'finely tuned machines' than those "trade" rods

were. Oh, there's that word that has seemed to become an evil

uttering! MACHINE! That's right . . . Machines. Hiram Leonard,

to the best of my knowledge, introduced the first machine to

rodmaking in the 1870's. This machine was a beveller that would

produce perfect strips to make the perfect rod. Contrary to what

many believe, Hiram Leonard only hand planed for a few short

years before he saw the obvious advantage of using machinery

and there IS an advantage to using quality machinery. Think

about it! If handwork were really all that accurate, then the

makers of finely tuned racing engines would be using files and

hand reamers instead of surface grinders and lathes. As for the

old milling and beveling machines of the trade rod company's,

Thomas and Thomas still uses the old Montague machines, and

makes some of the finest rods in the world on them today!

No, they couldn't compete with the Leonard's whose rods

were made on more 'finely tuned machines' than those "trade" rods

were. Oh, there's that word that has seemed to become an evil

uttering! MACHINE! That's right . . . Machines. Hiram Leonard,

to the best of my knowledge, introduced the first machine to

rodmaking in the 1870's. This machine was a beveller that would

produce perfect strips to make the perfect rod. Contrary to what

many believe, Hiram Leonard only hand planed for a few short

years before he saw the obvious advantage of using machinery

and there IS an advantage to using quality machinery. Think

about it! If handwork were really all that accurate, then the

makers of finely tuned racing engines would be using files and

hand reamers instead of surface grinders and lathes. As for the

old milling and beveling machines of the trade rod company's,

Thomas and Thomas still uses the old Montague machines, and

makes some of the finest rods in the world on them today!

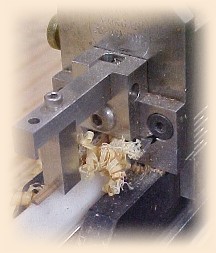

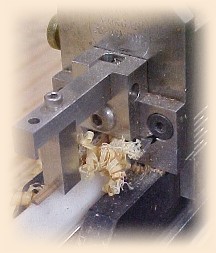

Please don't misunderstand; I have nothing against hand planing.

I hand planed well over 200 rods in my life. I've since moved

to a manually operated machine called the Morgan Hand Mill.

Why? Because it offers both ease of operation and more consistent

results. Even though I was very proud of my hand planed rods,

I quickly found I could produce a more consistent and better

quality blank with the Hand Mill than I could with a hand plane

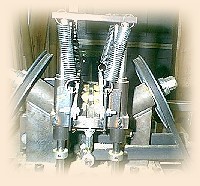

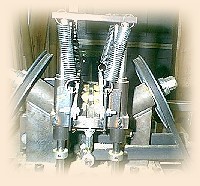

and a set of forms. Now, I'm making the move to a powered finish

beveller. Why, because, even though I'm proud of my hand milled

rods, I know the powered beveller will produce a more consistent

stick than either my planing forms or my hand mill. Sure, it

costs a lot of money to put something like that into operation.

If you started from scratch, a good bamboo miller or a good

beveller could cost thousands, even tens of thousands of dollars.

Spending that money is what part of the commitment is all about.

Putting your checkbook on the line to make better rods.

Now, I know up front I'm going to be challenged about hand

planing verses machining, but like I said, I've got on my

bulletproof vest, so fire away . . .but before you pull the trigger,

remember, the rods that the hand planers, even I when I was hand

planing, are doing their best to copy are Jim Payne's machine

built rods, Paul Young's machine built rods, The H.L. Leonard

Rod Company's machine built rods, H.L "Pinky" Gillum's machine

built rods, Thomas and Thomas's machine built rods, Winston's

machine built rods, and the list goes on and on and onů The

only maker I can think of that the majority of rodmakers who

hand plane will try to emulate the tapers of, is Everett Garrison.

Well, guys, I'm going to let you in on a little secret. In his

later years, Mr. Garrison's health was failing, and he was making

regular trips to the Leonard Rod Company's shop. When there, he

stated to an employee that if he were to ever try to go big with

his fly rods he would make a machine to make them. Yes, even the

man who all consider the ultimate hand planer, the one who most

in the craft consider the King of Rodmaking, dreamed of having

a power driven finish beveller. Mr. Garrison was a brilliant

man, and he knew and understood that the machines that turned

out such fine rods were "the way to go" if a man were to commit

himself to rodmaking as a living, rather than as a hobby.

Please, don't get up in arms too much! I'm not attacking hand

planing, I'm not attacking the Hand Mill (I will always keep

mine for doing my Quadrates) and I'm not attacking anyone who

will take the time and labor required to making a finely crafted

cane rod. All I'm saying is, just because someone wrote it in a

book, don't take it for granted that it is "THE" way to do it.

Hand planing is probably the best thing that ever happened to

hobbyists or low numbers production rodmakers, and I have a lot

of respect for hand planing. I've done a lot of it. I've done

a lot more of it than most rodmakers out there today. I've also

been a huge proponent of Tom Morgan's hand mill. It IS superior,

if one uses it properly, to hand planing. I'm also a big believer

in bamboo millers and bevellers. If used properly, they are

superior to hand planing and the Morgan Hand Mill, and in a

discussion on this subject, my friend Tom Morgan, former owner

of the R.L. Winston Rod Company (a company that has ALWAYS milled

their rods), and maker and marketer of the "Hand Mill," agreed.

He said that when he owned R.L. Winston that the machine they

used there, when properly tuned and adjusted, would turn out

perfect strips, with edges like razor blades.

Again, I don't want anyone to misunderstand, because I don't feel

there is a right way and a wrong way to make a rod. What I feel

is that there are easy ways and hard ways to make rods, and some

methods, by nature, are more precise than others. So, what do

I think about the different methods? In a nutshell, some hand

planed rods are great, some suck. Some hand-milled rods are

great and some suck. Some machined rods are great and some suck.

Not everyone can become a good rodmaker, not every rodmaker can

make a good rod, regardless of his methods or how many rods he's

made. You have to depend on a maker's reputation, his product

and his commitment. Know your maker; know more about bamboo

fly rods in general. Find a source for good bamboo fly rod

information and educate yourself. Find out what a good rod

is all about! Find out what a good rodmaker is all about!

Find out if that maker has made a commitment to his rodmaking

and to the quality, or if he's just trying to drag down a few

extra bucks turning out a few fishing poles. Bamboo fly rods

are expensive, so be sure you're making a good and wise

investment. Be sure your rodmaker has a commitment to the

craft that insures YOU are going to receive a quality rod.

Tom Morgan, in a telephone conversation that we had during

the writing of this article, told me that a rodmaker should

ask himself two questions . . . If this rod were being built

for you, would you want it? And if this were the only rod that

you made, that anyone would ever see, would you want everyone

to see it? If every rod turned out were put under the scrutiny

of those questions, there would be a lot less bamboo fly rods

floating around on the market today.

As for Hand Planing vs. Hand Milling vs. Machine Milling, a

very good friend of mine recently wrote that planing forms

were the wave of the future for rodmaking and I'm sorry, my

friend, but I must respectfully disagree. Hand planes were

the predecessor of the Milling and Beveling machines. They

came first, and until the "book" about Everett Garrison came

out, they were considered to be the "old way" not the wave

of the future. As much as I was, and still am, proud of my

planed rods, I knew from the time I planed my first rod that

this was how it was done back in the 1800's, not the way it

would be done in the future. There are probably more bevellers

and bamboo mills running today than there ever have been in

the history of rodmaking and I would bet a nice shiny new 5

weight that in 10 years, there will be a lot more of them in

shops around the country. Sure, there are more hand planers

out there too, I can't help but think that after a hundred

or so rods, they will sit in their recliner after a long day

in the shop and daydream of that magical machine that would

allow them to more efficiently make better rods. Not make

them faster, not make them prettier, but make them better.

~ R.L. "Bob" Nunley, Rodmaker

As for Hand Planing vs. Hand Milling vs. Machine Milling, a

very good friend of mine recently wrote that planing forms

were the wave of the future for rodmaking and I'm sorry, my

friend, but I must respectfully disagree. Hand planes were

the predecessor of the Milling and Beveling machines. They

came first, and until the "book" about Everett Garrison came

out, they were considered to be the "old way" not the wave

of the future. As much as I was, and still am, proud of my

planed rods, I knew from the time I planed my first rod that

this was how it was done back in the 1800's, not the way it

would be done in the future. There are probably more bevellers

and bamboo mills running today than there ever have been in

the history of rodmaking and I would bet a nice shiny new 5

weight that in 10 years, there will be a lot more of them in

shops around the country. Sure, there are more hand planers

out there too, I can't help but think that after a hundred

or so rods, they will sit in their recliner after a long day

in the shop and daydream of that magical machine that would

allow them to more efficiently make better rods. Not make

them faster, not make them prettier, but make them better.

~ R.L. "Bob" Nunley, Rodmaker

About Bob:

Bob Nunley is a full-time cane rodmaker who lives in

Poteau, OK. You can visit his

website at: www.caneflyrod.com , or by email at:

caneman@clnk.com.

If you would like to comment on this or any other article please feel free to

post your views on the FAOL Bulletin Board!

|

No, they couldn't compete with the Leonard's whose rods

were made on more 'finely tuned machines' than those "trade" rods

were. Oh, there's that word that has seemed to become an evil

uttering! MACHINE! That's right . . . Machines. Hiram Leonard,

to the best of my knowledge, introduced the first machine to

rodmaking in the 1870's. This machine was a beveller that would

produce perfect strips to make the perfect rod. Contrary to what

many believe, Hiram Leonard only hand planed for a few short

years before he saw the obvious advantage of using machinery

and there IS an advantage to using quality machinery. Think

about it! If handwork were really all that accurate, then the

makers of finely tuned racing engines would be using files and

hand reamers instead of surface grinders and lathes. As for the

old milling and beveling machines of the trade rod company's,

Thomas and Thomas still uses the old Montague machines, and

makes some of the finest rods in the world on them today!

No, they couldn't compete with the Leonard's whose rods

were made on more 'finely tuned machines' than those "trade" rods

were. Oh, there's that word that has seemed to become an evil

uttering! MACHINE! That's right . . . Machines. Hiram Leonard,

to the best of my knowledge, introduced the first machine to

rodmaking in the 1870's. This machine was a beveller that would

produce perfect strips to make the perfect rod. Contrary to what

many believe, Hiram Leonard only hand planed for a few short

years before he saw the obvious advantage of using machinery

and there IS an advantage to using quality machinery. Think

about it! If handwork were really all that accurate, then the

makers of finely tuned racing engines would be using files and

hand reamers instead of surface grinders and lathes. As for the

old milling and beveling machines of the trade rod company's,

Thomas and Thomas still uses the old Montague machines, and

makes some of the finest rods in the world on them today!

As for Hand Planing vs. Hand Milling vs. Machine Milling, a

very good friend of mine recently wrote that planing forms

were the wave of the future for rodmaking and I'm sorry, my

friend, but I must respectfully disagree. Hand planes were

the predecessor of the Milling and Beveling machines. They

came first, and until the "book" about Everett Garrison came

out, they were considered to be the "old way" not the wave

of the future. As much as I was, and still am, proud of my

planed rods, I knew from the time I planed my first rod that

this was how it was done back in the 1800's, not the way it

would be done in the future. There are probably more bevellers

and bamboo mills running today than there ever have been in

the history of rodmaking and I would bet a nice shiny new 5

weight that in 10 years, there will be a lot more of them in

shops around the country. Sure, there are more hand planers

out there too, I can't help but think that after a hundred

or so rods, they will sit in their recliner after a long day

in the shop and daydream of that magical machine that would

allow them to more efficiently make better rods. Not make

them faster, not make them prettier, but make them better.

~ R.L. "Bob" Nunley, Rodmaker

As for Hand Planing vs. Hand Milling vs. Machine Milling, a

very good friend of mine recently wrote that planing forms

were the wave of the future for rodmaking and I'm sorry, my

friend, but I must respectfully disagree. Hand planes were

the predecessor of the Milling and Beveling machines. They

came first, and until the "book" about Everett Garrison came

out, they were considered to be the "old way" not the wave

of the future. As much as I was, and still am, proud of my

planed rods, I knew from the time I planed my first rod that

this was how it was done back in the 1800's, not the way it

would be done in the future. There are probably more bevellers

and bamboo mills running today than there ever have been in

the history of rodmaking and I would bet a nice shiny new 5

weight that in 10 years, there will be a lot more of them in

shops around the country. Sure, there are more hand planers

out there too, I can't help but think that after a hundred

or so rods, they will sit in their recliner after a long day

in the shop and daydream of that magical machine that would

allow them to more efficiently make better rods. Not make

them faster, not make them prettier, but make them better.

~ R.L. "Bob" Nunley, Rodmaker