|

A few people have recently asked me how to build a

rod stand for making your own fly rod. I show a few

factory models and a homemade model built from a

cardboard box in my

rod building series, but I didn't

show how to build your own stand from wood.

I'm a firm believer in the idea of making things that

work for me, and keeping the plans flexible enough to

fit my needs exactly. However, my needs may not be your

needs, so what I would build for myself might not be

what you would need or want. I also use a power lathe

from Anglers Workshop in my regular rod building, so I

don't really need to build a wood rod stand.

That said, I decided to rebuild the old rod stand I loan

out on occasion, just so you can see how I would build one

on a budget. I have plenty of wood scraps in my garage

(remnants of the endless honey-do list), so I just whipped

this thing out from scraps I had and a few gadgets from

my old stand. If you had to buy everything I show here

new, it might cost you about 25 bucks, but most of that

price would be the thread tensioners you would have to

buy at a sewing center unless you can find a junker at

a second hand place. I didn't do any finish work on

this project, but instead whipped out a functional

stand that is long on function and short on looks.

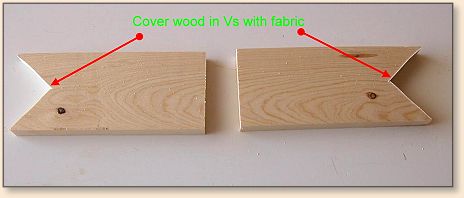

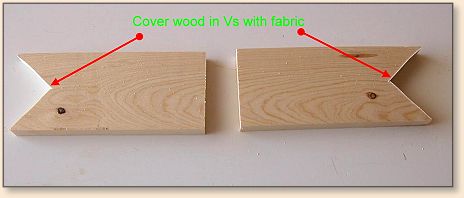

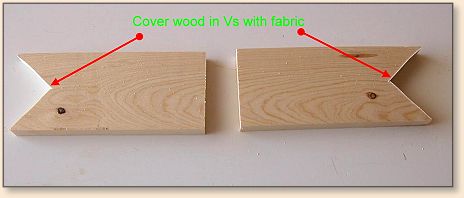

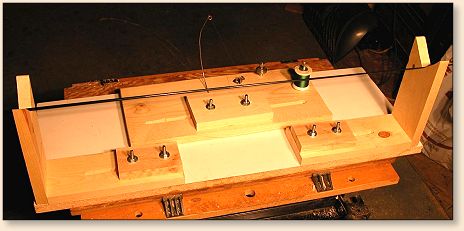

First I cut two 8" pieces of 1X4 pine to use as uprights.

I cut a notch in the top of each one to cradle my rod.

I'll cover the wood with felt later when I get near a

fabric store.

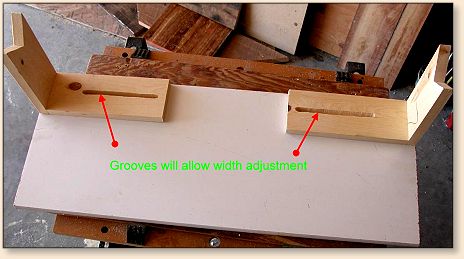

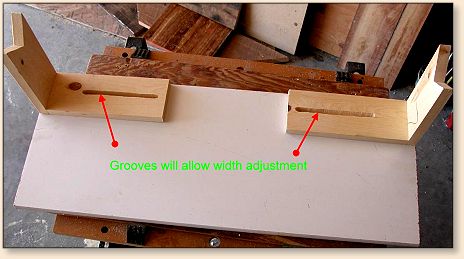

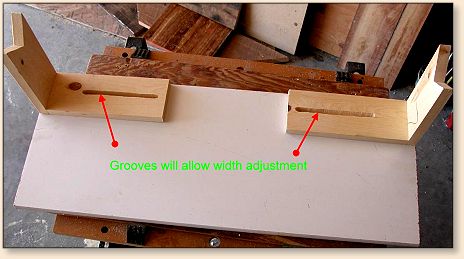

Next, I cut a couple of 10" long pieces of 1X4, cut some

slots in them with a Rotozip tool, and attached them to

my uprights with glue and screws. The grooves will allow

me to slide the uprights in or out to accommodate different

guide spacing. I'm using a scrap piece of white shelving

for the base.

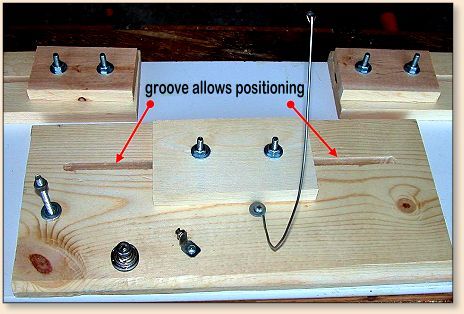

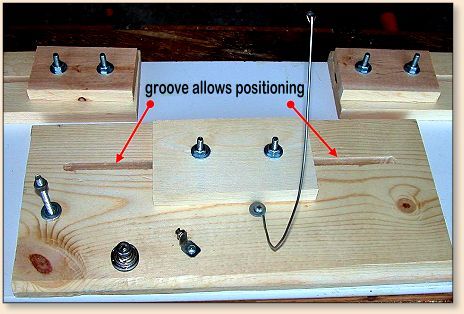

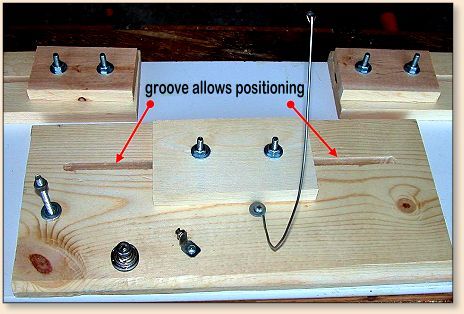

Then I zipped a slot in a scrap chunk of 1X8 that will

serve as a thread carriage. A few more scraps of wood,

some carriage bolts, some washers and nuts finished out

my basic stand.

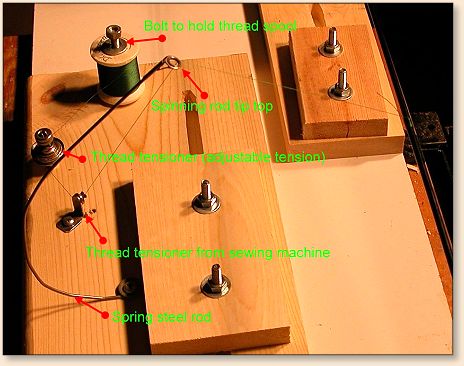

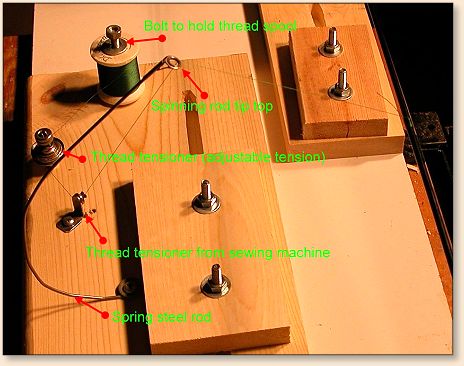

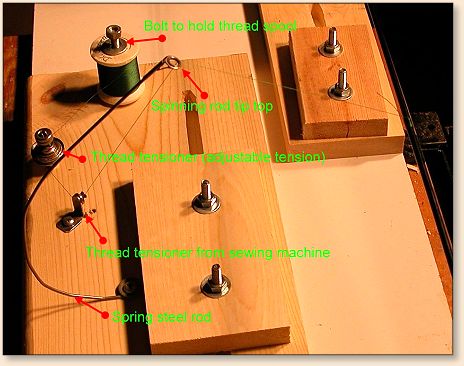

Thread routing and tensioning took a little more work.

I used another carriage bolt as a thread spindle to

hold my spools of thread. Then I added a basic thread

tensioner I salvaged from an old sewing machine many

years ago, and an adjustable tensioner I think I may

have bought at a yard sale about two decades ago. I

glued a spinning rod tip-top to a spring steel wire

and bent the wire to the right shape to guide my thread

to a place just above middle between the rod stands.

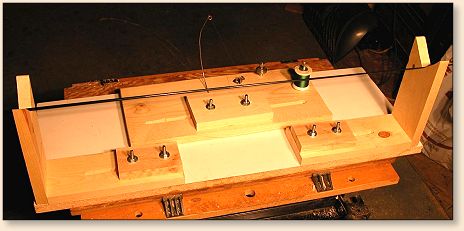

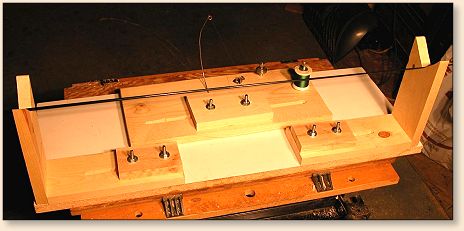

This is a view of the stand with a rod blank in the

cradles to show how it would look from the side you

would be working from.

And, this is a view from the side.

The whole project took a little more than an hour to

build. I used some scrap wood and a minimum of hardware.

I made everything adjustable so I could fit the stand

to any rod blank I would be using. It isn't pretty,

nor was it intended to be, but it is functional.

I hope this helps a few people to see how easy it is

to make your own rod stand for rod building. Yours

can be smaller or bigger as needed. You may not see

a need to make the uprights or thread carriage

adjustable. You might decide to just use one

thread tensioner, maybe the $2 non-adjustable type.

This is just one idea. You can create one that fits

your needs and size requirements easy. It only takes

a few pieces of scrap wood and a few bits of hardware.

Don't forget the felt to protect the rod blank from

the wood.

~ AC

|