Originally Posted by

Kaboom1

I have found that most of the tackiness problems come from weak batteries in your UV flashlight. New batteries will solve most of your problems.

Tackiness can be caused by weak batteries but the tackiness in fly tying resins is most often caused by the resin formulation.

The failure to cure is due to the chemical formula of the acrylic polymer. These resins will NOT cure with the relatively low power UV flashlights.

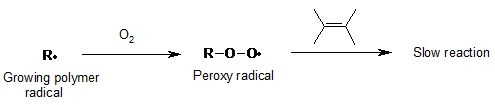

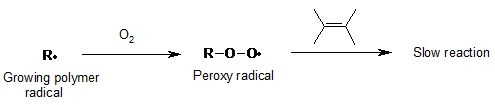

Acrylate polymers cure by free radical polymerization which is started and maintained by the UV light. However, with free radical polymerization, the exposed surface of the polymer allows the free radical to bind with atmospheric oxygen to create a peroxy radical that slows the polymerization at the surface. This is called oxygen inhibition. Oxygen inhibition slows down the polymerization process, and the result is peroxy radicals on the surface that are incompletely polymerized.

The "tackiness" is the uncured peroxy radical polymer in reaction below:

Those who have taken basic chemistry know that every liquid, including liquid polymers are in a steady state with the oxygen in our atmosphere. So there is some dissolved O2 in liquid polymers. Oxygen inhibition also occurs under the surface and this weakens the inside of the ?cured? polymer.

If the polymerization is done in the absence of oxygen in a nitrogen atmosphere, or in a vacuum, the surface would polymerize.

The solution to a tacky surface is not to add a second coat that also fails to polymerize. The solution is to modify the chemistry of the acrylic polymer so that it is resistant to oxygen inhibition. There are such polymers and there are research papers on ways to minimize oxygen inhibition.

When I did my research into these polymers I found the problem was NOT finding an acrylic polymer formula that would resist oxygen inhibition. You can find them, but they are expensive to make especially in small quantities.

The problem is finding an acrylic polymer that is cheap enough to be used in fly tying, that has enough oxygen inhibition resistance to cure tack free with the thicknesses used in fly tying, that can be made in small amounts, and that can be completely cured with the hand held low power UV flashlights.

Last edited by Silver Creek; 04-06-2018 at 06:43 PM.

Regards,

Silver

"Discovery consists of seeing what everybody has seen and thinking what nobody has thought"..........Szent-Gyorgy

Reply With Quote

Reply With Quote