I have often been asked how to make a drying motor, and have also found this to be a frequent question on various web site bulletin boards. As a result I felt it may be of some use to put together instructions on how mine was done. A drying motor can be constructed with the basic around the house tools at a cost of about $25.00.Required Tools

- 1. Drill & Bits2. 2 in Hole saw.

3. Miter box with a back saw ($12.95 at Wal-Mart).

4. Screw driver.

Materials list

- 1. 36 RPM drying motor $12.95 (Jann's Netcraft)2. Wood stock 4in X 2 ft X 1/2in 1 each (I use poplar from the local lumber yard $2.49 Each).

3. Electrical cord $1.95.

4. Screws.

5. Self stick felt.

Instructions

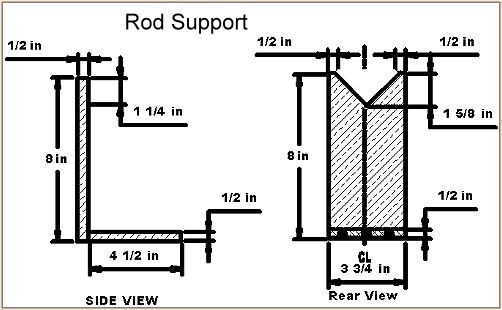

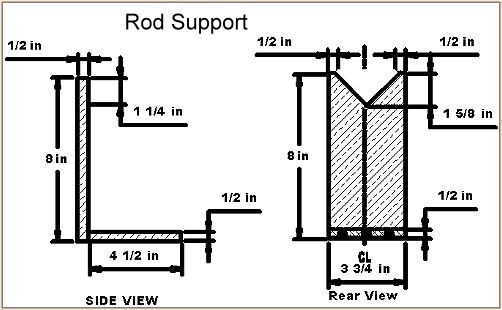

The instructions for this are straight forward.The stock that I use comes sized for length and width at ? inch thick and is available in Pine, Oak, Poplar and Ash. By purchasing the material in this manner all cuts can be made with a Back Saw and a Miter box.The V cut on the support is accomplished with the back saw. The cut for the motor was done with a hole saw and the motor has its own mounting flange.For a cord a replacement cord was used and the connections were covered with small shrink tubing. An on/off switch can be added if one wishes. The spindle on this motor will accept a self-centering chuck if one wishes.When building a rod the last step for me is to secure the reel seat. Making this my last step accomplishes two things. First I do not have the weight to deal with and second I use old blanks cut to various lengths to secure the rod to the motor thus saving about $22.95. I pick up the old blanks for $5.00 at the pawn shop.For an Epoxy I use U-40 LS Supreme (Dura Gloss) and apply it with Box Wood modeling tools. Replacement syringes can be purchased at a farm and ranch supply for about $.29 each.I hope this Drying Motor works as well for you as it has for me and that the cost is within a range that you can accept. Since all things can be improved. If you find a modification that makes for better operation, let me know so it can be shared with all. ~Brian Ahern (Rovercat)

|

Reply With Quote

Reply With Quote