Hello. I've been wanting to photo document one of my builds for a while now for my own purposes and am finally getting around to doing it. I thought if there was interest that I would post the step-by-step process on the board as I go along. I thought it might be neat for others to see.

Anyway, I am building a 10'8" 7wt switch rod for myself. This will be a new addition to my steelheading arsenal to replace a rod I broke last year. I'm not a super fast builder so dont expect this to go at lightening speed. I basically only work on it after my son has gone to sleep and a bit on the weekends. I already have a bit of a jump on the build so I hope you enjoy the photos. Stay tuned for more as I make progress on this rod.

Heres the complete set of starting materials. Batson 10'8" 7wt Switch rod blank, American Tackle Braided Window reel seat, TITAN titanium stripping guides (size 16 and 12) REC recoil heavy wire snake guides, Cork (regular, burnt, copano and dalmation rubberized)

Here is a closer look at some of the components

The first step for me was to work on the handle. I normally turn handles out of exotic hardwoods on my lathe so it has been a while since I have made a custom cork handle. I like the wood handles but it just wont work for this rod as the handle will be pretty large.

I had an idea in my head of what I wanted for a handle and it involved some thin trim bands of burnt cork. Time to make a jig.....Here is the scrap piece of wood I used to make the jig.....

Using a Forstner bit of the appropriate size I drilled out 4 shallow holes of varying depth....each hole would be for a different thickness cork trim band (assuming I will want different thickness trim pieces for different handles in the future).

Next thing was to get the jig lined up on the bandsaw. I wanted the blade of the saw to run flush with the surface of the jig.....

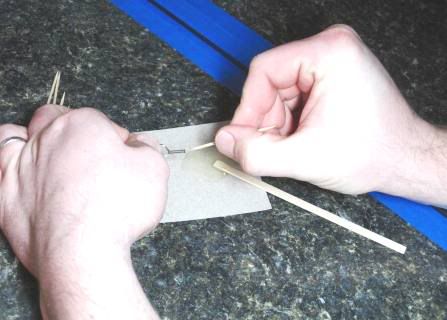

Here's a photo of the jig in use. I use a push stick to hold the cork square into the previously drilled holes. The bandsaw slices off the body of the cork and you are left with a nice thin ring the depth of the hole....

As you can see the jig works pretty well yielding trim rings 3/32 inch thick and all uniform. Not bad for a jig that didnt cost me anything but a few minutes of time....

Next step was to ream out all of the cork and make sure it fit well on my gluing mandrel....

Next was to play with different orientations of the cork and arrive at a design that I liked. This is what I ended up liking......

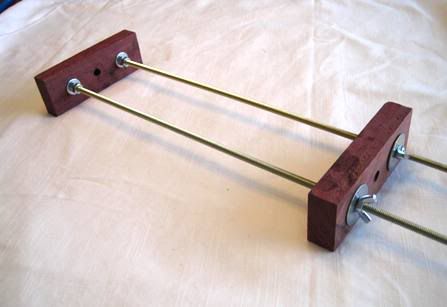

I glued the butt piece together first. This piece is about 5 inches long so I just used a threaded rod. Apply painters tape first to the areas where the cork will be and then rub with parrafin wax to make sure the epoxy doesnt stick to the mandrel.

I'm hitting my limit now for # of pics in a post so thats it for now, I'll post more very soon.

Hope you enjoy.

Yonks

Reply With Quote

Reply With Quote